Multifunctional 3230DT provides power for additional depth with ability to quickly switch between drilling methods to achieve efficient completion of mining sector projects.

Robert and his brother Michel established Technofor in February 2003 with Michel completing environmental work with their first drill rig — a Geoprobe® 6610DT. When Robert’s son, Aimé Emard, joined the company in 2021, they sought a way to add rock coring to their skillsets.

“We were missing 90% of jobs, which were predominantly in the mining sector,” Emard, operations manager, said. “Needing to get into that sector and looking for our first rock coring drill, we purchased a Geoprobe® 7822DT.”

However, the company located in Quebec, Canada, didn’t have anyone with diamond tooling experience. Emard, a self-described engineer and mechanic, stepped up to the challenge.

“I learned at the back of the 7822DT,” Emard said.

According to him, their 7822DT outperforms the competition.

“We were on site with a competitor where our 7822DT completed 0 to 100 feet faster than three other drills. The customer called and couldn’t understand how we were doing it,” Emard said. “It was because we were using more than one drilling method thanks to the multifunctionality of the drill.”

During 2022, they took their next step in mining exploration by purchasing a used Geoprobe® 8040DT.

“The 8040DT provided more power, increasing our ability to go deeper in tough soils,” Emard said. “It hit the right spot to go forward at not too steep a price.”

The 2009 model 8040DT was in need of extensive repairs, but with the help of Geoprobe® International Service Rig Specialist Roman Burrows, they completed the majority of the rebuild in Quebec.

“With his help, we changed the motor and surrounding components,” Emard said.

Technofor leveraged the versatility of their used 8040DT to become even more competitive for rock coring contracts. According to Emard, they're in the top three for rock coring in their area thanks to the 8040DT (no longer in production).

“Geoprobe® offers multipurpose rigs that give us an edge over a traditional rig. It’s better and faster for that size of drill,” Emard said. “The first time a client saw the 8040DT, they thought it was too small, but realized if used right with diamond coring it can do the job even better.”

3230DT for Mining Exploration Peace of Mind

With two drilling teams and two rigs, Technofor desired extra assurance they could take care of customers. So during 2024, they expanded their fleet — once again with Geoprobe®.

“Because Geoprobe® rigs are multifunctional, it’s rare to be stuck in a field without knowing what to do. You can combine two methods of drilling in the same borehole. We’ve learned to drive casing using the percussion hammer for the first 1/3 of a job. This is fast with less hassle of water and gives client quick information,” Emard said. “We next complete rock coring, which requires managing water so it’s slower. With the Geoprobe® rigs we can switch faster between the two methods, saving 25% in time and better serving our clients.”

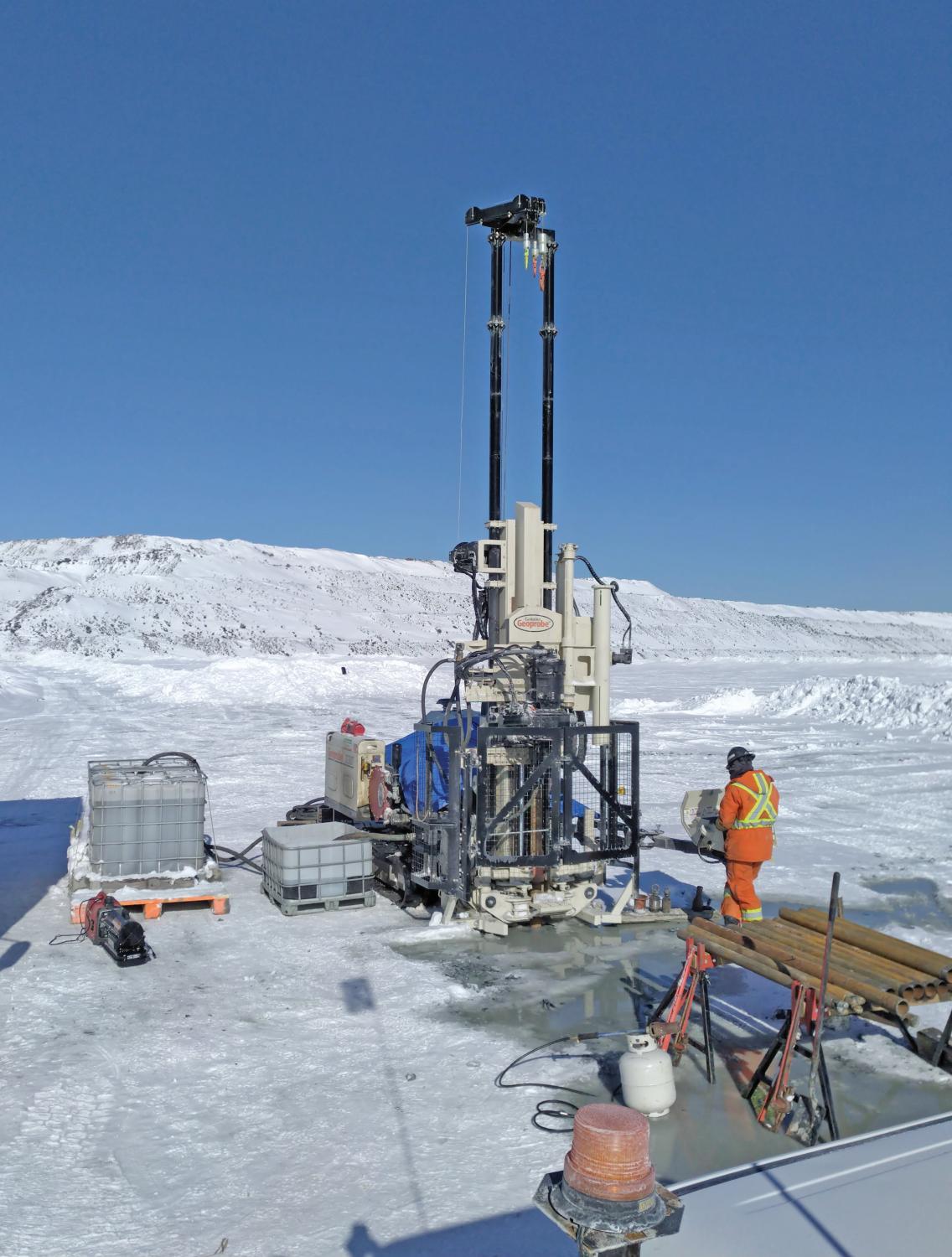

The majority of their mining exploration job sites entail woods, rock, swamp, or deep snow, so the tracks on their next rig were critical. They also wanted the maximum head power. This led them to the 3230DT.

“The 3230DT would give us the ability to drill a deeper hole plus the ability to get into smaller jobs,” Emard said. “We received it at the end of 2024, immediately drilling in cold, wet weather.”

Beyond tracks and power, the 3230DT provides Technofor additional advantages.

- Patented CB combo head with centerline head side shift: “The head incorporates multiple functions combined with the 4-speed that’s easy to change. When working, you can move the head assembly out of the way to have clear access to the center of the tool string.”

- Triple winch with telescoping mast and outriggers: “The outriggers and mast maneuverability mean we can position the drill before drilling and easily correct position without totally moving the drill using the easy control panel functions.”

- Built-in patented hydraulic head clamp: “The clamp on the top head and the jaw assembly means whatever conditions we’re in, we can pull it out. With conventional rigs we would still be stuck. With the 3230DT there’s no slipping of the tooling, it just comes right out.”

- Movable, adjustable control panel: “There’s so much detail from the 3230DT control panel regarding rig performance you can modify your approach to the boring so you can manage a successful project even in the worst conditions. You can do all kinds of miracles with these drills if you know how to use them.”

Supportive Service

Because Technofor often drills in extremely cold temperatures, international service support from Geoprobe® helped them make some modifications to overcome cold weather challenges.

“Rather than having to ship it back across the border and deal with all that paperwork, Roman found us a shop in Toronto to help us,” Emard said. “The mechanic there was new on the 3230DT, but with Roman’s help was able to help us solve our cold functionality problems.”

Technofor now has 22 years of environmental and geotechnical experience — all with Geoprobe® rigs.

“We’ve chosen to stay with Geoprobe® because they are strong and easy to repair, but for drilling, the 3230DT is like a Cadillac,” Emard said. “It’s not overpowered and can drill all the time really smoothly. I could almost drill from home because it’s so easy.”

Stages of Mineral Exploration Jobs

Tailings: “We install, via direct push, instrumentation into the mining waste beds to assess soil pressure.”

Mine expansion: “We characterize the top soil and rock. We’ll come in after the exploration, traversing the woods in deep snow trying to minimize support equipment to complete all geotechnical borings. They want big samples through the fill to let them know what type of minerals are present.”

Exploration: "Most of the time we use diamond tooling for rock coring 100 feet into rock to ensure they could fulfill the exploration picture."

Grouting: “We’re grouting all the time so there’s no connection between the ground layers for groundwater to move into. Sometimes we install piezometers or monitoring wells, but most of the time it’s grouting.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Double breakout on the 3230DT shines on a unique geothermal energy loop project.

ID: 14605 | Date:

Along with extra torque and rpm, 3135GT features like weight-on-bit, hands-free rotation, and three winches make rock coring easier.

ID: 14601 | Date:

SRC30DT sonic rod carrier creates virtually hands-free job sites when paired with 8150LS like on this exploration project in Queensland, Australia.

ID: 14597 | Date:

8150LS V3 provides ergonomic operations while powering through tough formations on a dam project.

ID: 14595 | Date:

Want to see Geoprobe® Sonic power in action? Geoprobe® is ready to bring our sonic system to you!

ID: 14546 | Date:

Related Videos

ID: 14189

Geoprobe® Sonic Drilling Products

ID: 14188

ID: 13740

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461