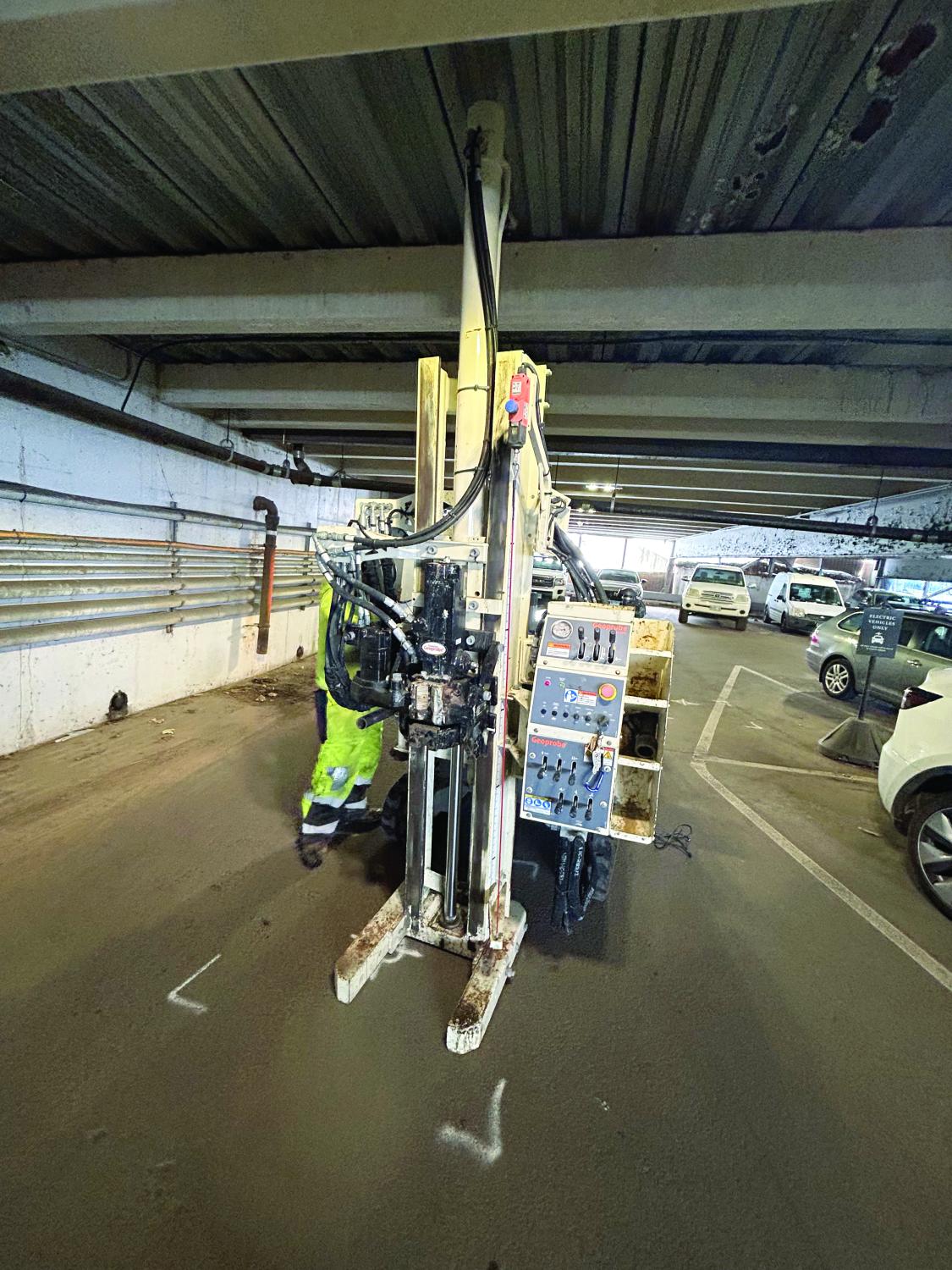

Indoor, low-clearance sites are no match to the power of the GH63 hammer on the 6011DT.

By Dirk Barry

Cisco Geotechnical put their new 6011DT to work at Yale University's Wright Laboratory drilling soil samples from around the bunker buildings housing the 100-foot long Van De Graaff Particle Accelerator. The particle accelerator was constructed in 1966. For 50 years the building rumbled to life, operating at 22 million volts to propel atoms at 10 million miles per hour as researchers anxiously awaited solutions to the great mysteries in nuclear physics. The accelerator was operated until it was decommissioned in 2011.

"The lab is undergoing major construction projects to make way for the next ground breaking innovations in science," Dirk Barry, operations manager, said.

Cisco chose the 6011DT machine for its ability to work in low clearance and narrow work areas.

"Major construction activities and a very congested work area demanded we think small," Barry said. "Even with the limited access abilities of the 6011DT, the powerful GH63 hammer might not be able to smash atoms but was definitely able to collect the samples required by the engineering team."

Drilling Soil Samples

The drillers used a combination of traditional 5-foot Macro-Core® sleeves for drilling soil samples in narrow areas around the lab as well as short 2-foot tooling that allowed them to operate inside the adjacent parking garage, which had just 9 feet of overhead clearance.

"Unfortunately, the only dark matter Cisco was able to find on this project was in the Macro-Core® sleeves collected during the two weeks on site," Barry said. "The 6011DT can stick to the heavy soil sampling and leave the heavy ion work to the Yale scientists."

Installing Injection Wells

The Cisco team also completed the install of 15, 2-inch injection wells with their 6011DT, operating in the bottom level of a parking garage in downtown Boston’s theater district.

"The crew was 50-feet below street level, pushing through Boston’s blue clay with just 9 feet of overhead clearance in the drilling locations. Even less clearance was required when tracking between the locations," Barry said. "Short 2-foot sections of 3.75-inch tooling were utilized to drive in the injection wells."

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date:

Geoprobe® international service expertise keeps the 7822DT working in the field, not sidelined in the shop.

ID: 14613 | Date:

Pullback power of 7822DT outperforms conventional rigs, overcoming sand friction when driving 4-inch casing.

ID: 14608 | Date: