Tooling and Drilling Rig Manufacturer

Launched in 1987, Geoprobe Systems® manufactures innovative drilling rigs and tooling - engineered to simplify fieldwork - empowering drilling companies to succeed as productive and profitable industry leaders. We incorporate customer feedback to continuously develop solutions to make drillers’ jobs faster, easier, and safer, across water well, geothermal, cathodic protection, geotechnical, environmental, exploration and construction drilling industries.

Applications

Whether you specialize in a single drilling application or offer a variety of service lines, you’ll find a drilling rig and tooling system suited to making your job faster, easier, and most importantly safer. Guided by feedback from the field and focused on producing the best possible soil probing and drilling equipment, our team of skilled engineers and craftsman continually develop, manufacture, and test new and innovative drill rigs and drilling tooling for the technical drilling industry. From rotary drilling, percussion drilling, and sonic drilling our goal is fieldwork simplified so you succeed.

Geotechnical

Advance ahead of the competition with centerline head side shift and hands-free controls on powerful drill rigs engineered to trim time between techniques while enabling you to expand your scope of work.

Environmental

Lead an ever-changing environmental drilling market with compact, versatile drill rigs engineered by the originators of direct push technology to make jobs safer and easier - propelling your profit potential.

Exploration

Excel in the global exploration industry which requires cost-effective drilling options with compact drill rigs engineered for versatility and speed reducing investment, operation, and mobilization costs.

Water Well

Dominate in the high demand water well drilling market with drilling rigs engineered to make water well, geothermal, and cathodic protection drilling speedy and efficient – saving you time and money.

Geothermal

Outpace the competition and exceed production predictions in tough site conditions with drill rigs engineered to withstand the rapid-pace of repetitive borings required in geothermal drilling.

Drilling Rigs

When you're seeking the fieldwork simplified to complete your drilling faster, easier and safer, count on Geoprobe® drill rigs engineered for versatility and manufactured for reliability. Industry leaders depend on our ongoing commitment to innovation and industry-leading customer support to advance their business ahead of the competition. Digital readouts providing instant feedback, enhanced safety features, easy operation, and availability of training options mean veteran drillers find their jobs simplified while new drillers build confidence, making them productive as they're quickly coming up the learning curve.

Whether you’re facing consolidated materials, glacial till, or backfill rubble, quickly complete complex holes to greater depths with the powerful GV5 50K sonic head on our line of sonic drill rigs. Engineered by Geoprobe® to advance up-to 12-inch tooling, the GV5 produces torque required to maintain rotation in tight formations – all backed by a 2-year warranty.

8250LS Sonic Drill Rig

Quickly provide continuous, undisturbed core samples to impressive depths utilizing 20-foot tooling with the 8250LS sonic drill rig.

8150LS Sonic Drill Rig

Increase depth advancement and recovery speeds while minimizing waste with the 8150LS sonic drilling rig engineered for driller safety, sampling speed, and operation efficiency.

SRC30DT

Simplify sonic drilling using self-propelled sonic rod carrier with dual quick-attach 10-foot rod magazines.

Geoprobe® combination drill rigs possess the power to tackle difficult site conditions combined with the versatility to exceed subsurface sampling expectations to equal business growth in both direct push and rotary drill rig applications.

3230DT Drill Rig

Combine geotechnical augering and high-speed rotary with advanced direct push capability to offer additional services to your customers, quickly going from coring rock to pushing CPT - all in one drill rig.

7822DT Drill Rig

From crowded street corners to far removed places, tackle various environmental, geotechnical and exploration applications with a single machine combining rotary drilling and direct push, saving time and money required to mobilize multiple drill rigs.

In a geotech industry ruled by rate-per-foot, Geoprobe® geotechnical drill rigs capable of swiftly sliding from rotary to automatic drop hammer, even to CPT or direct push — without having to move drill mast or machine — position you for increased production and profit.

3126GT Geotechnical Drill Rig

Save time and effort swiftly sliding the innovative centerline head side shift into position for rotary, automatic drop hammer, even CPT or direct push. No need to move the geotechnical drill or drill mast on the compact, off road drill rig.

3145GT Geotechnical Drill Rig

Punch out power and pipe line projects with efficiency and performance of 31 series drill mast aligning all head and winch functions over the bore hole combined with creature comforts of a crawler carrier.

3100GT Geotechnical Drill Rig

Efficiently complete geotech investigations sliding between drilling functions all without the need for a class A/B CDL, safely bringing new drillers up the learning curve on the drilling truck.

3135GT Geotechnical Drill Rig

Geoprobe® 3135GT drill rig has 10,000 ft-lb of torque and 1,000 rpm to power through your geotechnical projects whether they need augering, mud rotary, SPT, Shelby tubes, hard rock cores, or CPT.

Maximize the value of your investment by choosing a CPT drilling platform best suited to your specific business model. Whether you’re seeking a dedicated CPT drilling rig or a versatile drilling rig to run a variety of applications, you’ll find the combination of features to push your business ahead.

20CPT Press

Expand CPT access with lightweight, compact 20CPT Press and tailor your CPT rig by mounting to a skid steer or on a 6712DT small drill rig.

Generating a name for itself and redefining the way sites are investigated in the environmental industry, Geoprobe® continues to advance direct push drilling through continued innovation of its line of high-quality, hydraulically-powered direct push drilling rigs

6712DT Drill Rig

Engineered to separate into sections for helicopter transport, the 6712DT leverages its Tier 4 engine for additional power and control to make environmental work easier.

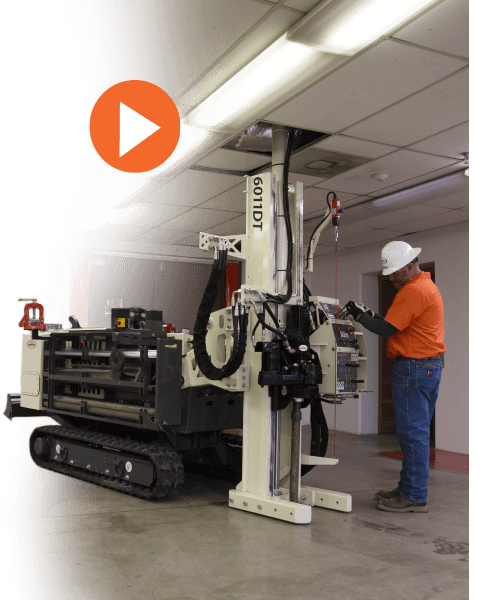

6011DT Drill Rig

Featuring a proven GH63 percussion hammer and able to use 5-foot tooling, the 6011DT direct push drill rig is still being sized to slip into small spaces.

5410 Drill Rig

Complete small to medium direct push jobs with probe and tools transported in a single rig with the 5410 truck mounted drill rig.

540MT Drill Rig

Access remote sites or tight spaces using the dollie-mounted 540MT limited access drill rig with reliable direct push power.

420M Drill Rig

Manually lift and carry the 420M portable drill rig into hard-to-reach job sites with a mast weight less than 450 lbs.

With the necessary tophead rotation speed, head feed speed, and plenty of mud pump options to get the job done, complete your water well drilling, geothermal drilling, and cathodic protection drilling jobs with a single, compact water well drill.

DM250 Water Well Drill Rig

From simple operation and surprising power to fast production with 20-foot stroke, DM250 offers loads of added value all under class A/B CDL.

DM450 Water Well Drill Rig

Tophead offering both torque and speed to the impressive power to weight ratio make the DM450 well suited for water well, geothermal, and/or cathodic protection drilling while minimizing maintenance.

DM650 Water Well Drill Rig

Outfit as down the hole drill or mud drill with the power of 28.5-foot stroke, 40,000 lb pullback, and 8,000 ft-lb torque to handle deeper wells along with weight of steel casing.

Drilling Rigs

When you're seeking the fieldwork simplified to complete your drilling faster, easier and safer, count on Geoprobe® drill rigs engineered for versatility and manufactured for reliability. Industry leaders depend on our ongoing commitment to innovation and industry-leading customer support to advance their business ahead of the competition. Digital readouts providing instant feedback, enhanced safety features, easy operation, and availability of training options mean veteran drillers find their jobs simplified while new drillers build confidence, making them productive as they're quickly coming up the learning curve.

Whether you’re facing consolidated materials, glacial till, or backfill rubble, quickly complete complex holes to greater depths with the powerful GV5 50K sonic head on our line of sonic drill rigs. Engineered by Geoprobe® to advance up-to 12-inch tooling, the GV5 produces torque required to maintain rotation in tight formations – all backed by a 2-year warranty.

8250LS Sonic Drill Rig

Quickly provide continuous, undisturbed core samples to impressive depths utilizing 20-foot tooling with the 8250LS sonic drill rig.

8150LS Sonic Drill Rig

Increase depth advancement and recovery speeds while minimizing waste with the 8150LS sonic drilling rig engineered for driller safety, sampling speed, and operation efficiency.

SRC30DT

Simplify sonic drilling using self-propelled sonic rod carrier with dual quick-attach 10-foot rod magazines.

Geoprobe® combination drill rigs possess the power to tackle difficult site conditions combined with the versatility to exceed subsurface sampling expectations to equal business growth in both direct push and rotary drill rig applications.

3230DT Drill Rig

Combine geotechnical augering and high-speed rotary with advanced direct push capability to offer additional services to your customers, quickly going from coring rock to pushing CPT - all in one drill rig.

7822DT Drill Rig

From crowded street corners to far removed places, tackle various environmental, geotechnical and exploration applications with a single machine combining rotary drilling and direct push, saving time and money required to mobilize multiple drill rigs.

In a geotech industry ruled by rate-per-foot, Geoprobe® geotechnical drill rigs capable of swiftly sliding from rotary to automatic drop hammer, even to CPT or direct push — without having to move drill mast or machine — position you for increased production and profit.

3126GT Geotechnical Drill Rig

Save time and effort swiftly sliding the innovative centerline head side shift into position for rotary, automatic drop hammer, even CPT or direct push. No need to move the geotechnical drill or drill mast on the compact, off road drill rig.

3145GT Geotechnical Drill Rig

Punch out power and pipe line projects with efficiency and performance of 31 series drill mast aligning all head and winch functions over the bore hole combined with creature comforts of a crawler carrier.

3100GT Geotechnical Drill Rig

Efficiently complete geotech investigations sliding between drilling functions all without the need for a class A/B CDL, safely bringing new drillers up the learning curve on the drilling truck.

3135GT Geotechnical Drill Rig

Geoprobe® 3135GT drill rig has 10,000 ft-lb of torque and 1,000 rpm to power through your geotechnical projects whether they need augering, mud rotary, SPT, Shelby tubes, hard rock cores, or CPT.

Maximize the value of your investment by choosing a CPT drilling platform best suited to your specific business model. Whether you’re seeking a dedicated CPT drilling rig or a versatile drilling rig to run a variety of applications, you’ll find the combination of features to push your business ahead.

20CPT Press

Expand CPT access with lightweight, compact 20CPT Press and tailor your CPT rig by mounting to a skid steer or on a 6712DT small drill rig.

Generating a name for itself and redefining the way sites are investigated in the environmental industry, Geoprobe® continues to advance direct push drilling through continued innovation of its line of high-quality, hydraulically-powered direct push drilling rigs

6712DT Drill Rig

Engineered to separate into sections for helicopter transport, the 6712DT leverages its Tier 4 engine for additional power and control to make environmental work easier.

6011DT Drill Rig

Featuring a proven GH63 percussion hammer and able to use 5-foot tooling, the 6011DT direct push drill rig is still being sized to slip into small spaces.

5410 Drill Rig

Complete small to medium direct push jobs with probe and tools transported in a single rig with the 5410 truck mounted drill rig.

540MT Drill Rig

Access remote sites or tight spaces using the dollie-mounted 540MT limited access drill rig with reliable direct push power.

420M Drill Rig

Manually lift and carry the 420M portable drill rig into hard-to-reach job sites with a mast weight less than 450 lbs.

With the necessary tophead rotation speed, head feed speed, and plenty of mud pump options to get the job done, complete your water well drilling, geothermal drilling, and cathodic protection drilling jobs with a single, compact water well drill.

DM250 Water Well Drill Rig

From simple operation and surprising power to fast production with 20-foot stroke, DM250 offers loads of added value all under class A/B CDL.

DM450 Water Well Drill Rig

Tophead offering both torque and speed to the impressive power to weight ratio make the DM450 well suited for water well, geothermal, and/or cathodic protection drilling while minimizing maintenance.

DM650 Water Well Drill Rig

Outfit as down the hole drill or mud drill with the power of 28.5-foot stroke, 40,000 lb pullback, and 8,000 ft-lb torque to handle deeper wells along with weight of steel casing.

Tooling

We never stop designing at Geoprobe®. It is why we come out with so many new tools and tooling systems. We want to maximize your performance in the field.

A great drilling machine isn’t much use without a proper tooling system. When machines and tools are designed, built, and supported as one, the end result is a highly refined system that benefits field users, business owners, and project managers alike. Click on a link below to learn more..

Drill Rig Service Team Support

With drill rig service shops in Kansas, Florida, Pennsylvania, and North Carolina, you’ll have industry-leading drill rig service team support nearby for your routine maintenance or more in-depth rig remounting and refurbishment.

Factory Service Center

1835 Wall Street • Salina, Kansas 67401 • (785) 825-1842

Southeast Service Center

5801 SW 6th Place • Ocala, Florida 34474 • (352) 854-1566

East Coast Service Center

468 Limestone Rd • Oxford, PA 19363 • (610) 467-1750

North Carolina Service Center

2515 US Highway 70 SW • Hickory, NC 28602 • (828) 998-0977

News & Resources

Learn about the key features of our equipment.

See how our customers have had success with our drilling rigs.

Telemetry Service: Real-time Drill Rig Insights

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

From High School Job to Family Well Drilling Business

Refurbished Schramm T450 outperforms expectations for family-owned drilling company.

Driltech Downtime to Drill Time

Used Driltech rig receives multiple service sessions to stay field-ready for the long term.

60 Day Not 6 Month Drilling Rig Repair

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.