8150LS V3 includes new unmatched 3-year/1,000 hour GV5 sonic drill head warranty, beefed up breakout to handle range of tooling diameters, and adjustable height control panel. Next generation controls incorporate larger display and increased reliability. Sensitive components have been relocated to increase reliability while maintaining serviceability.

Evaluating service records documented from phone calls made by owners of sonic drills provided the road map to re-engineering the Geoprobe® 8150LS. Engineers paid particular attention to improving sonic work field performance and reliability to reduce overall operating costs. Some subtle changes like moving valves out of danger zones, removing duplicate sensors, and simplifying fluid cooling reduces risk for breakdowns while maintaining accessibility. Other enhancements include:

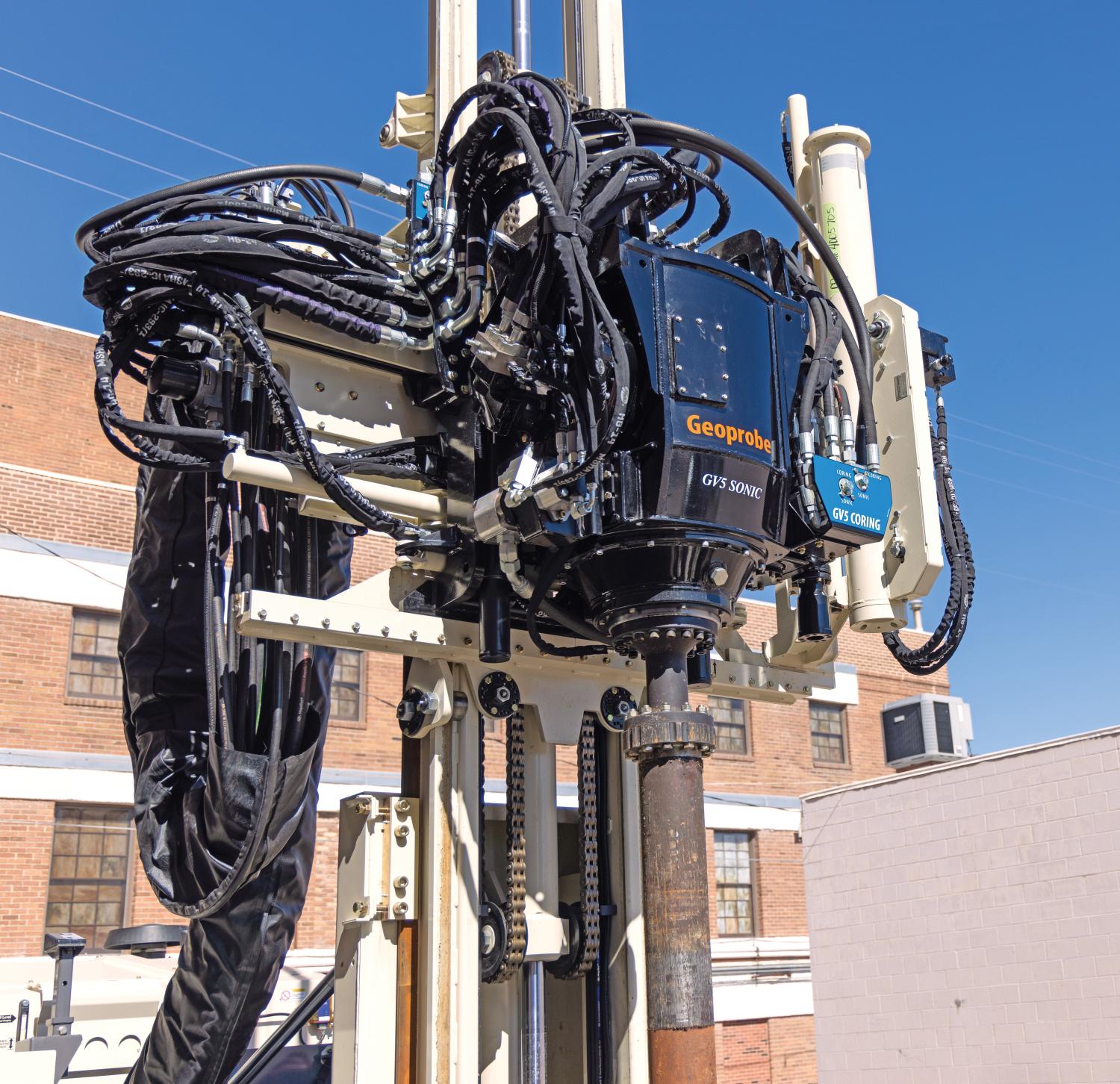

GV5 Sonic Drill Head — 50K Power and Durability

New 8150LS sonic drills now come with class-leading 3-year/1,000-hour GV5 sonic drill head warranty. Historically, sonic operators worldwide have struggled securing a sonic drill head providing both performance and durability. Geoprobe® engineers responded to the challenge through continual innovation of our sonic drill head design to package both power and robust head life into the GV5 sonic drill head. Regardless of subsurface formation or operator experience, Geoprobe® GV5 sonic heads receiving basic maintenance keep running. Sonic work from Turkey to New Zealand and all points in between rely on the GV5 sonic drill head to stand the test of time, eliminating the need to tie up capital to keep an extra sonic drill head on the shelf.

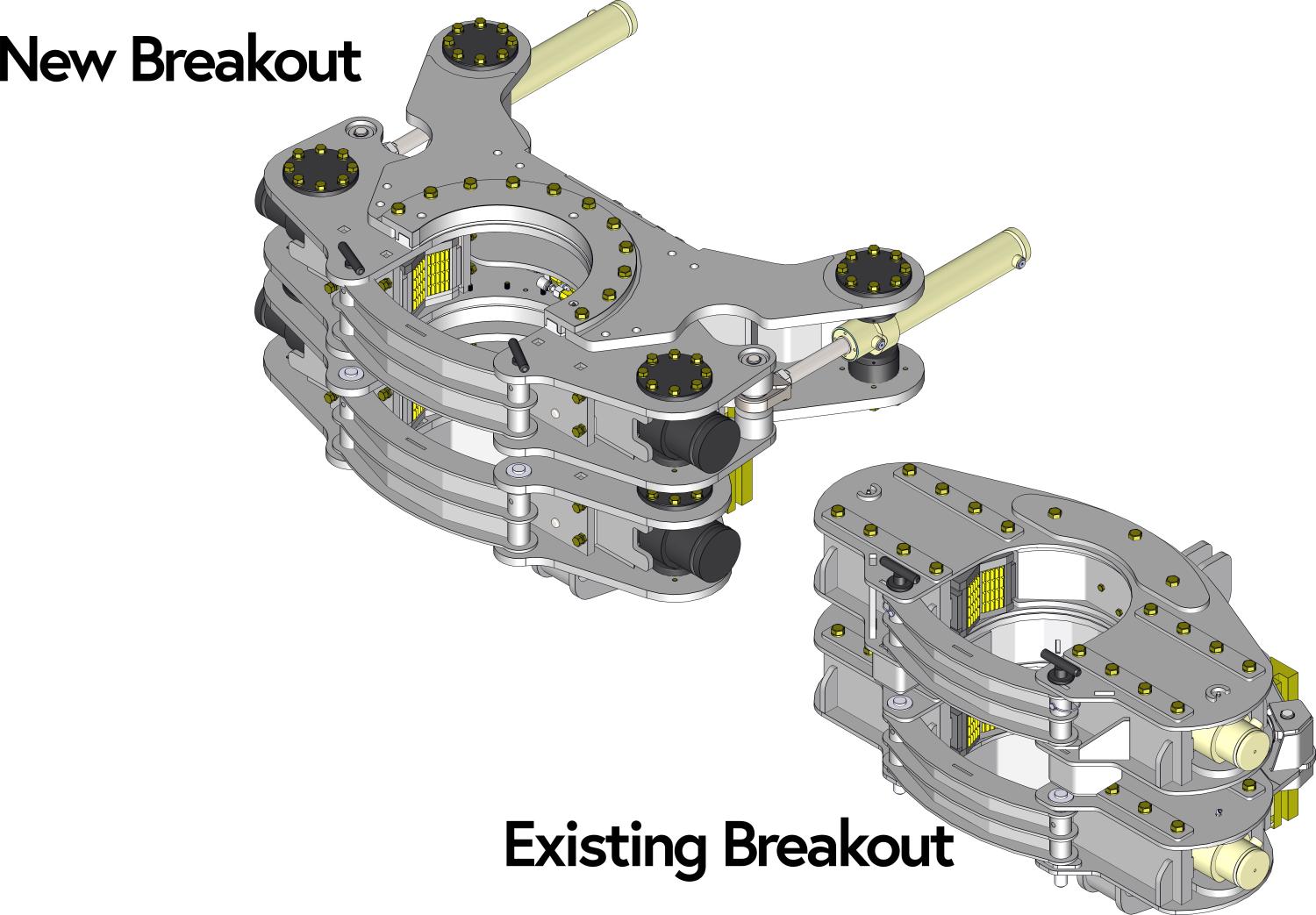

More Robust Breakout

The double wrench breakout on the 8150LS sonic drills makes quick work of breaking tool strings. Striving for perfection, Geoprobe® engineers designed a new robust breakout to improve the ability to handle a range of tooling diameters from 2- to 14-inch casing. The new design incorporates:

- increased clamp force from 21,000 to 31,000 lbf

- increased twist force from 13,500 to 37,000 ft-lb

The re-engineered breakout not only addresses performance, but also improves serviceability. Now common wear components can be replaced versus requiring replacing the entire breakout.

Rod Handling System Simplifies Sonic Work

Reduce operator fatigue and injury while increasing productivity and safety with the optional rod handling system. Handles large diameter, 5- and 10-foot rods and casing, minimizing heavy lifting. Adjustable angles permit precise head alignment.

Pairing with optional SRC30DT self-propelled rod carrier or one of the many indexing rack options, including the new stack rack, creates a nearly hands-free sonic work operation without sacrificing drilling performance.

Engineered to handle multiple rod and casing sizes, drillers can operate rod handler from the driller's platform minimizing manpower required on sonic work site. Uneven terrain or the amount of mud on the rod doesn't prohibit performance.

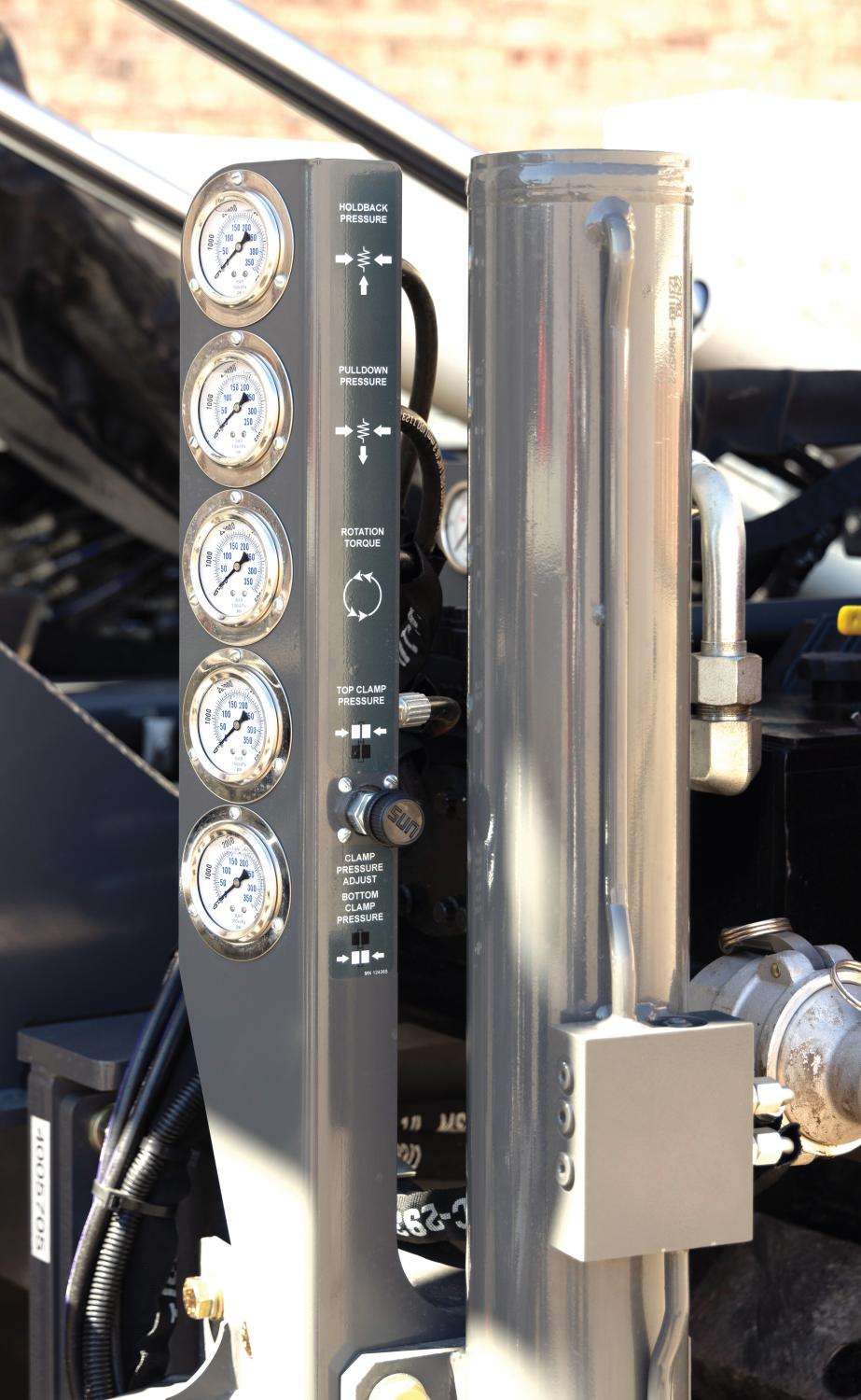

Adjustable Height Control Panel

Next generation controls include a larger display and increased reliability, as well as simplified weight-on-bit. Housed on an adjustable height control panel to optimize operator comfort, the swing-arm on our sonic drills allows driller to position control panel as close or as far from tool string as desired.

Bank of five analog displays indicate:

- Holdback pressure

- Pulldown pressure

- Rotation torque

- Top clamp pressure

- Bottom clamp pressure

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 8150LS fits inside a 40-ft. shipping container - perfect for overseas shipment.

ID: 14616 | Date:

Geoprobe® engineered and manufactured GV5 sonic head with DMR7 rotary head along centerline head side shift to position over hole without moving machine.

ID: 14598 | Date:

SRC30DT sonic rod carrier creates virtually hands-free job sites when paired with 8150LS like on this exploration project in Queensland, Australia.

ID: 14597 | Date:

Geoprobe® manufactured 3.5 and 6.0 sonic casing.

ID: 14596 | Date:

Related Videos

ID: 14189

Geoprobe® Sonic Drilling Products

ID: 14188

Geoprobe® Sonic Stack Rack Overview

ID: 14115

ID: 12781

ID: 1922