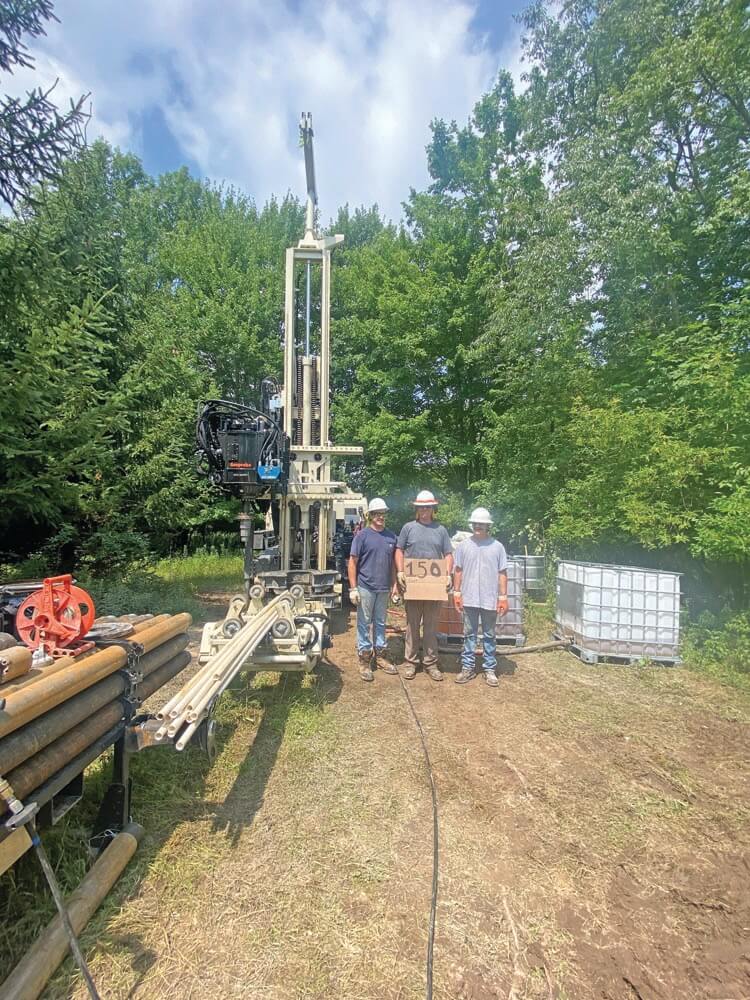

Adding sonic drilling services saves time, reduces physical strain, and produces less waste on environmental investigation looking for PFAS in Ionia, Michigan. L to R: Jack Price, Brian Lower, Eli Brintlinger.

In the environmental drilling industry for two decades, Scott Densteadt has seen it come full circle.

“When I started, all we did was drill hollow stem auger or mud rotary. Then direct push side of things really took off and became the standard. However, this limits achievable depths,” Densteadt said. “Now it's coming full circle with more requests for drilling, but you want to collect the best lithological data possible and hollow stem auger is a crude method.”

A drilling supervisor for the geological services section in the Remediation and Redevelopment Division of Michigan Department of Environment, Great Lakes, and Energy (EGLE), he describes his job as “protecting the environment for the citizens of the state of Michigan.”

“We complete assessments in order to return Brownfield sites back to beneficial use like parks and new businesses,” Densteadt said. “We conduct environmental investigations statewide and provide written reports to our district staff."

Recognizing sonic sampling provides a good lithological core every time in half the time as hollow stem auger, they conducted a study comparing how much the state was paying outside contractors for sonic drilling services versus costs to add those services in-house.

“We determined we could do it ourselves for a cost savings,” Densteadt said. “We looked at other manufacturers, but our past positive working relationship and customer service along with a lower price point, enabling saving tax-payer money, steered the decision toward the Geoprobe® 8150LS.”

Densteadt and his team spent three days in Kansas participating in hands-on training with Geoprobe® Sonic Specialists Jed Davis and Joel Christy prior to delivery of their 8150LS.

On their first job in northern Michigan, the site was predominantly glacial til and sand with solvents coming from different sources. The team worked with the Environmental Protection Agency and the Army Corp of Engineers to complete vertical aquifer samples and soil samples. Geoprobe® Sonic Specialist Jed Davis joined the geological services team on site.

“His presence was priceless,” Densteadt said. “He helped us work through some site challenges.”

This included identifying a PFAS-free lubricant for the threads.

“Lots of pipe lubricants have PFAS in them and that was one of the contaminants in the water there,” Densteadt said. “We didn’t want to contribute to the detection levels so it took a lot of trial and error to eventually find a suitable lubricant.”

Ability to rely on Geoprobe® for assistance on simple things like lubricant to challenges like sampling techniques drove them toward the Geoprobe® sonic rig and tooling line.

“Geoprobe® and its service has always been top notch," Densteadt said. “If you’ve got a problem, someone is always there to point you in the right direction."

The team returns to the northern Michigan site soon to drill air sparge and injection wells.

They appreciate the speed at which the 8150LS can drill and collect the quality soil cores a geologist needs to do their job effectively.

According to Densteadt, compared to hollow stem auger drilling, the sonic rig has also:

- Saved time achieving depth,

- Reduced physical strain,

- Produced fewer spoils.

“Coming from hollow stem auger, sonic drilling is way better and faster, especially in difficult formations where high-quality sampling is a priority,” Densteadt said.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Geoprobe® Introduces Drill Rig Telemetry to the Drilling Industry — monitor rig operations easily through our customer portal, Centerpoint Connected.

ID: 14625 | Date:

The 4.25 HSA Continuous Sampler is versatile and easy to use when collecting large sample volumes.

ID: 14619 | Date:

The 8150LS fits inside a 40-ft. shipping container - perfect for overseas shipment.

ID: 14616 | Date:

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date: