DM250 provides desired efficiency in tight sites, taking hours versus days to complete wells, with ease of operation desired by next generation drillers.

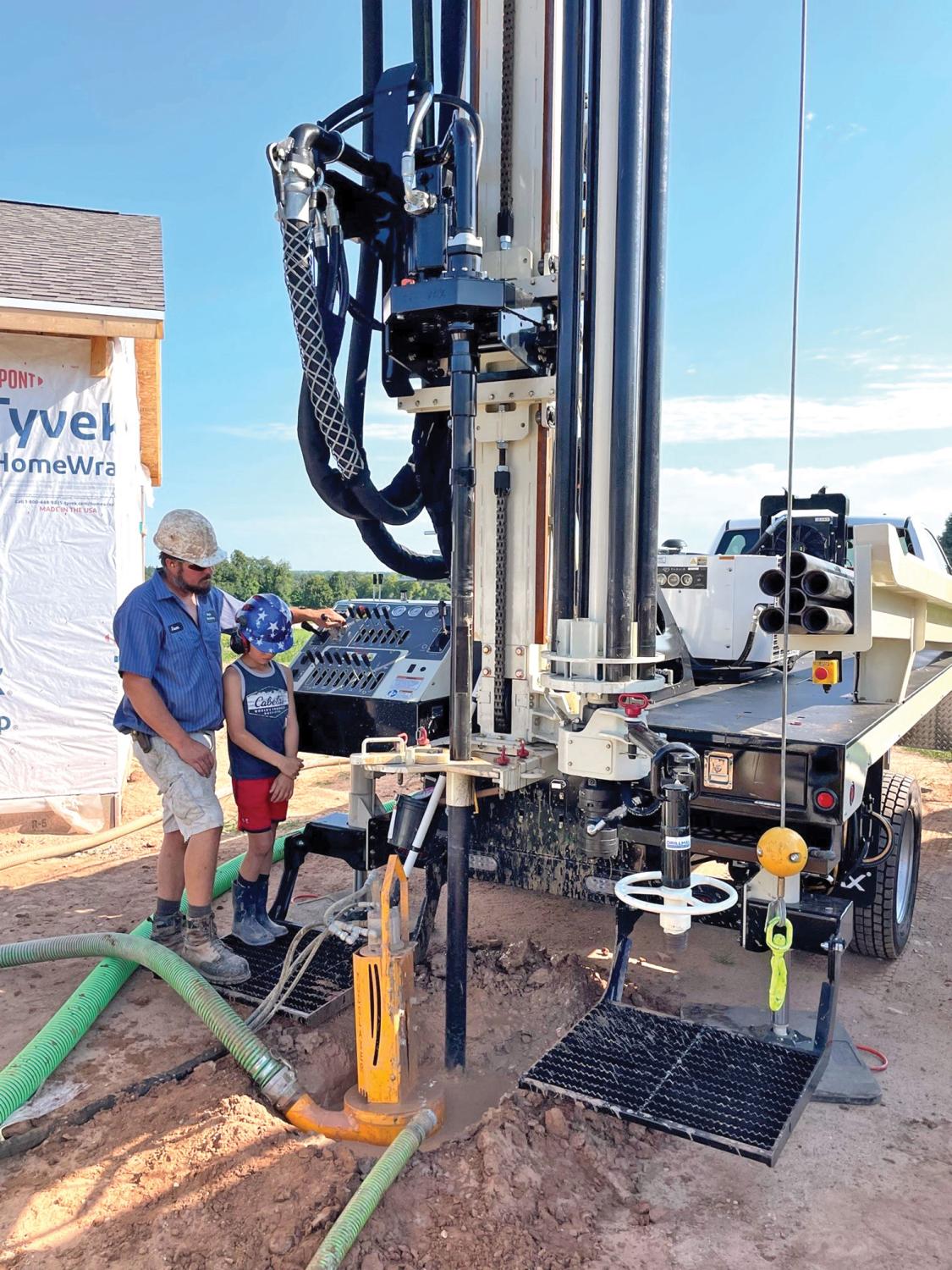

You’ll often find Jason Hintzke’s nephew — a fifth generation driller — out running their DM250 for the family drilling business, Hintzke Well Drilling. The company has been operating since 1896, living and working out of the same location in Wisconsin.

“My great-grandpa built our first well rig in 1902 because nothing else worked in our area,” Hintzke, owner, explained. “It’s wood, iron and rope, and ran until a few years ago.”

The company drills steel and PVC wells using a TH60 for mud, T3W for casing hammer, and now their DM250 for mud and development air. While they’ve always done pump installation, they’re now drilling for many other contractors. Their drilling jobs take them in a radius of two hours around their shop, but they try to keep the pump crew within an hour radius.

“We want to be out drilling,” Hintzke said. “We’re drilling residential, farm, and commercial wells. We recently completed a project for a ranch supporting 5,000 head of cattle.”

Hintzke didn’t even realize he was in the market for the DM250 until he saw it at the National Ground Water Association show in Nashville.

“We talked to Donnie [Wood, product line manager] and the guys who had purchased the display rig,” Hintzke said. “It was a no brainer once we talked about it.”

Running the rig during a factory tour of the Geoprobe® manufacturing headquarters in Salina, Kansas, sealed the deal.

“All other rigs have the controls on the passenger side, but it only took about 20 minutes to figure out the driver’s side controls on the DM250,” Hintzke said.

Advantages Over Cable Tool Drilling Rig

The Hintzke family sought out a new water well rig for increased efficiency in tight sites. Their cable tool drilling rig required screening everything and would take a day or two to complete the well.

“With the DM250, it takes a couple of hours and uses minimal fuel,” Hintzke said. “It’s also much more comfortable than the old cable tool drilling rig.”

For Hintzke, there’s no shortage of things to like about the DM250:

- Fast, variable speed rotary head: “Most of the time we run at medium; we don’t even need high.”

- Top head travel speed: “It’s crazy fast.”

- Efficient rod carousel: “Most of our PVC wells are 160-feet, but we got the optional rod box in case we need to go deeper and our stabilizer fits in there.”

- Comfortable 4-wheel drive chassis: “It’s our only rig with 4-wheel drive and with AC and radio. It’s comfortable driving and doesn’t require a CDL.”

- Updated hydraulic table: “It’s so tight, it’s not slapping around and doesn’t rattle. We can break bit joints with the breakout wrench on-site versus at the shop. We could even set steel casing if we wanted to.”

These features combined with user-friendly, quiet operation caused their cable tool drilling rig to be moth balled the past two years.

“Once you get the hang of it, you don’t ever have to look up. The head slows down as it reaches the top. So if you’ve got a sore neck, this is the rig for you. It’s user-friendly, and you don’t have to jump up onto the stands. We wear ear plugs, but we wouldn’t need them it’s so quiet,” Hintzke said. “At first we were still drilling PVC wells with other rigs, but now we choose the DM250 because it’s so much easier.”

Hintzke also appreciates the DM250’s reliability.

“We’ve drilled 200 wells, and only had to tighten a few hoses and change the packing one time,” he said. “We’ve never had a brand new rig that didn’t have troubles. We’ve had no problems.”

The fuel efficiency means they can run all day and barely use any fuel.

“We can drill two to three 120-foot wells with an hour of travel in between before having to fuel up,” Hintzke said. “We can’t even get our big rigs to the site for the cost of traveling plus drilling with the DM250.”

On the occasions when they do have to opt for one of the big rigs, the next generation of drillers has a smooth transition.

“My nephew loves drilling with the DM250 and has no problem going back and forth between the DM250 and T3,” Hintzke said. “It’s just a fast machine that’s so much easier. We’re even drilling for the competition when they can’t get their big rigs on site.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date:

Related Videos

DM Water Well Rig Series Overview

ID: 14052

Geoprobe® Walkaround: DM650 Air Rig

ID: 14045

ID: 14042

ID: 14040