Nuclear Magnetic Resonance (NMR)

Nuclear Magnetic Resonance (NMR), a widely used borehole wireline logging technology in the petroleum industry for characterizing hydrocarbon reservoirs, has been adapted for hydrological investigations within monitoring wells and open boreholes. During the last two decades, technological innovations have significantly increased the efficiency of NMR as a field characterization approach by reducing tool size (from more than 6 inches down to 1.75 inches in diameter) and measurement time (from 15 minutes to less than 90 seconds per interval). Recently, Geoprobe Systems® in conjunction with Vista Clara Inc., Washington, has developed the DP NMR Dart probe for 2.25-inch direct push applications.

What Is Nuclear Magnetic Resonance?

NMR works by using an induced magnetic field to affect and align the nucleus of the hydrogen atoms within water molecules. A high-voltage electrical current is pulsed through a coil of shielded wire at the specific resonant frequency of hydrogen nuclei. This ‘excites’ the nuclei, causing them to realign with the induced field. Next, the current is turned off; as the nuclei ‘relax’ to the original state, they generate an electromagnetic response signal that is measured on the same coil that was used to excite them.

Because the recorded NMR signal is emitted directly by hydrogen nuclei in water, it directly measures the total amount of water within the measured zones and the relaxation rate of water molecules, the latter of which is sensitive to the size distribution of pore spaces. Smaller pore sizes result in short T2 relaxation times, larger pore sizes result in longer relaxation times. These measurements allow us to measure the volumetric water content within the formation, as well as estimate the subfractions of mobile, capillary, and bound water.

Uses of Nuclear Magnetic Resonance

NMR has been shown very effective for estimating critical aquifer properties governing the flow and storage of groundwater, such as porosity and permeability. These properties have been of great interest to regional water boards looking to determine areas of high groundwater storage capacity where managed aquifer recharge is being considered. Porosity (which under saturated conditions, is directly measured by NMR) can also greatly affect the bearing capacity of soils which can be of great geotechnical interest for construction as well as within mine tailings.

To deploy the DP NMR Dart via direct push, 2.25-inch empty casing is driven to depth with an expendable point. Upon reaching terminal depth, the NMR Dart with logging cable attached is lowered to the bottom of the rod string using extension rods. After adding water to the rod string to prevent sediment clogging, the outer casing is retracted to expose the Dart probe to the formation. NMR logging is performed as the rods are retracted back to the surface. Measurements of the NMR Dart are obtained at 5.5- and 6-inch diameter surrounding the Dart probe, well beyond the 2.25-inch driven casing disturb zone.

DP NMR Dart Applied to Kansas Geological Survey Research Site

The DP NMR Dart probe has been applied at a Kansas Geological Survey research site (LRS, or Larned research site). LRS, located in the Arkansas River valley near the city of Larned in west-central Kansas, was established for studying stream-aquifer interactions and riparian zone processes. The shallow unconsolidated subsurface at the site consists of three major units: the Arkansas River alluvial aquifer at the top, a clay-dominated confining layer in the middle, and the High Plains aquifer (HPA) resting on Pennsylvanian bedrock (shale and limestone) at the bottom.

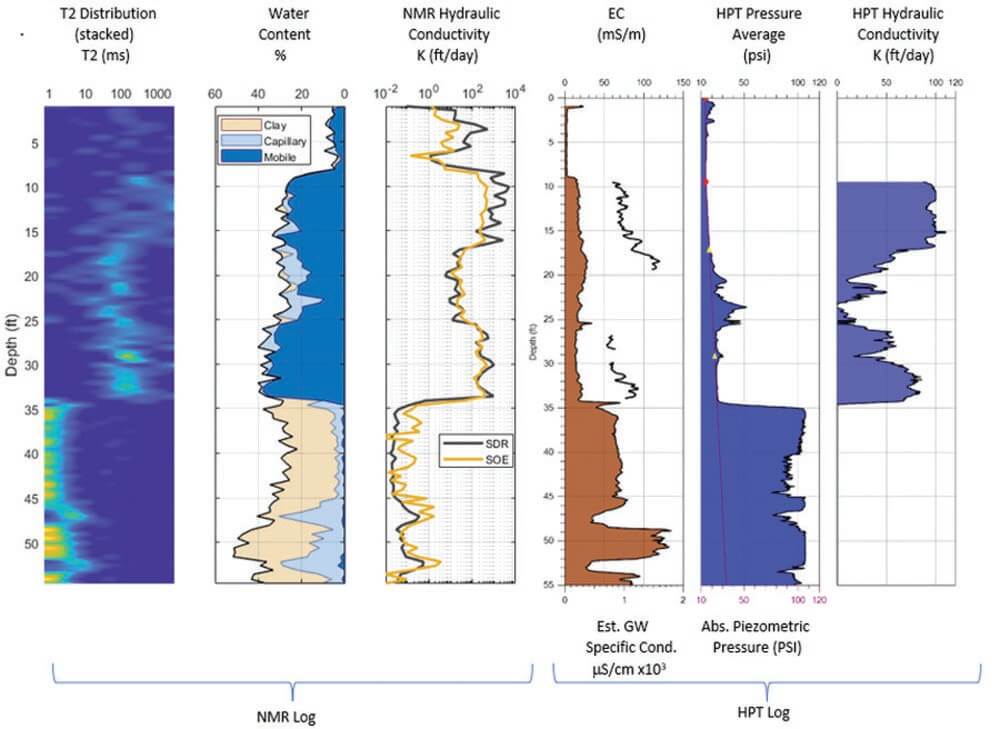

A Hydraulic Profiling Tool (HPT) log and DP NMR log (1.5-feet apart) display very comparable lithology at LRS (see log at left). At the water table (9 feet), the NMR-measured water content shows an abrupt increase. The HPT indicates the alluvial aquifer contains a significant amount of low-permeability, fine-grained sediments, as displayed by the increase of injection pressure between depth 17 and 26 feet. Within the same zone on the NMR the percentage of capillary water increases while mobile water percentage decreases, indicating smaller pore size. The estimated hydraulic conductivities (K) show similar general trends between NMR and HPT, however, the range of K on NMR is orders of magnitude above and below what is possible with HPT.

In the middle clay zone, at 47 to 48 feet, the percentage of capillary water increases while the percentage of clay water decreases, corresponding to the decrease of EC and injection pressure in the HPT log. Similar observation can be made at 52 to 53 feet.

Importantly, the application of DP NMR at LRS illustrates its great potential for characterizing low-permeability zones. The HPT has a low detection limit for hydraulic conductivity and cannot provide estimates in the middle clay layer. The NMR, by contrast, provides effective characterization of water in both large and small pores.

"Future works should be performed to establish the use of NMR in low-permeability formations," said Gaisheng Liu, associate scientist at Kansas Geological Survey.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Enhanced safety and reduced physical strain placed on your team proves invaluable when weighing cost of investing in a sonic rig system.

ID: 14159 | Date:

When evaluating sonic drill rig options, keep an eye toward simplifying your fieldwork. Look for features to safely succeed in even the most challenging drilling scenarios while maintaining reliable production and minimizing operation costs.

ID: 14158 | Date:

Beyond physical rig components, evaluate a manufacturer’s ability to offer extensive support services to ensure you get the most out of your equipment.

ID: 14157 | Date:

Manufacturing productive sonic drill rigs requires more than just engineering prowess. Innovations are more effective when those skilled engineers are also experienced in operating the sonic rig themselves.

ID: 14156 | Date:

In a wide range of formations, a single sonic drilling rig can quickly provide continuous, undisturbed core samples to impressive depths while preserving the option for setting wells - often at less cost per foot.

ID: 14155 | Date:

Related Videos

ID: 6608