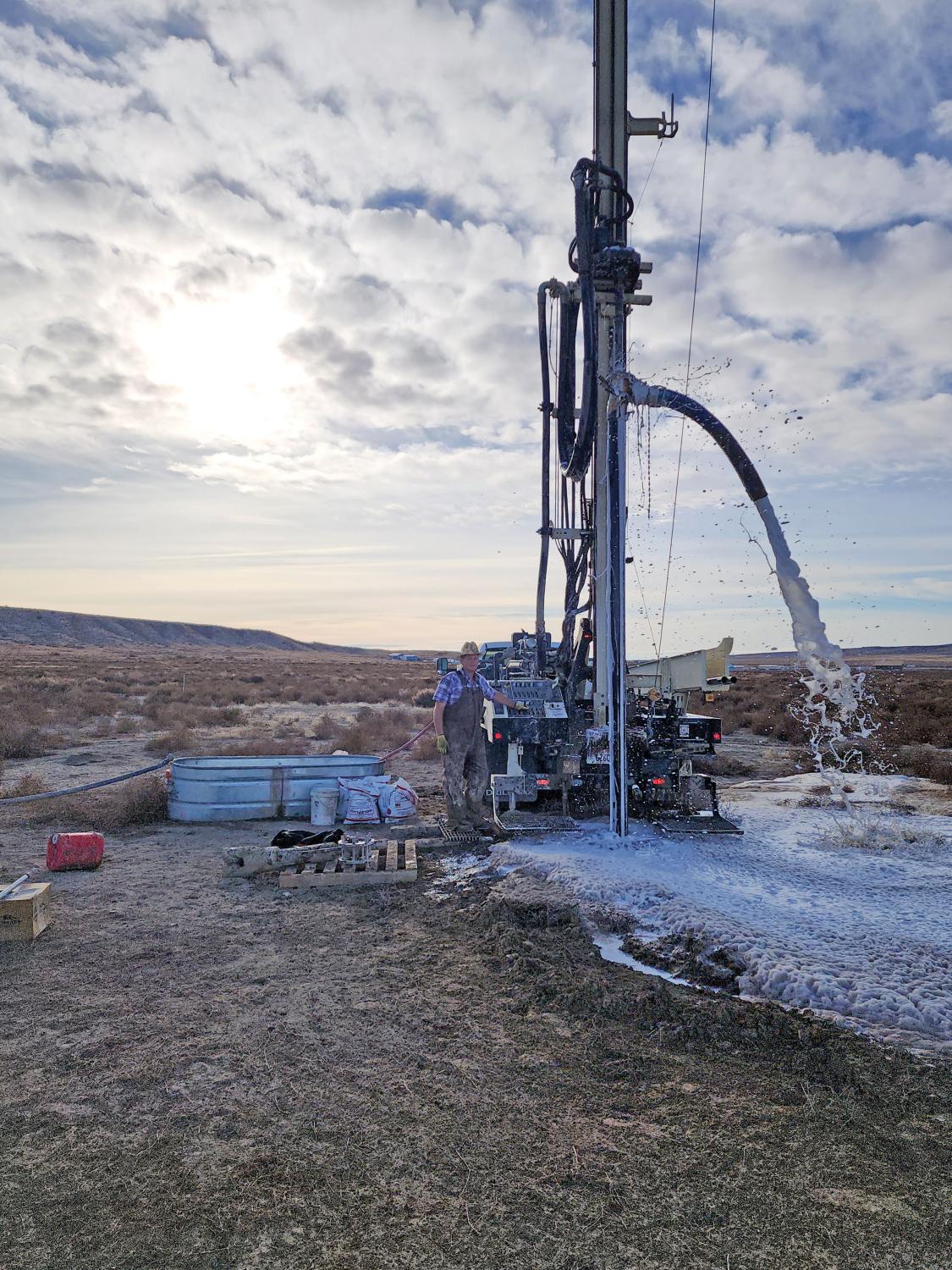

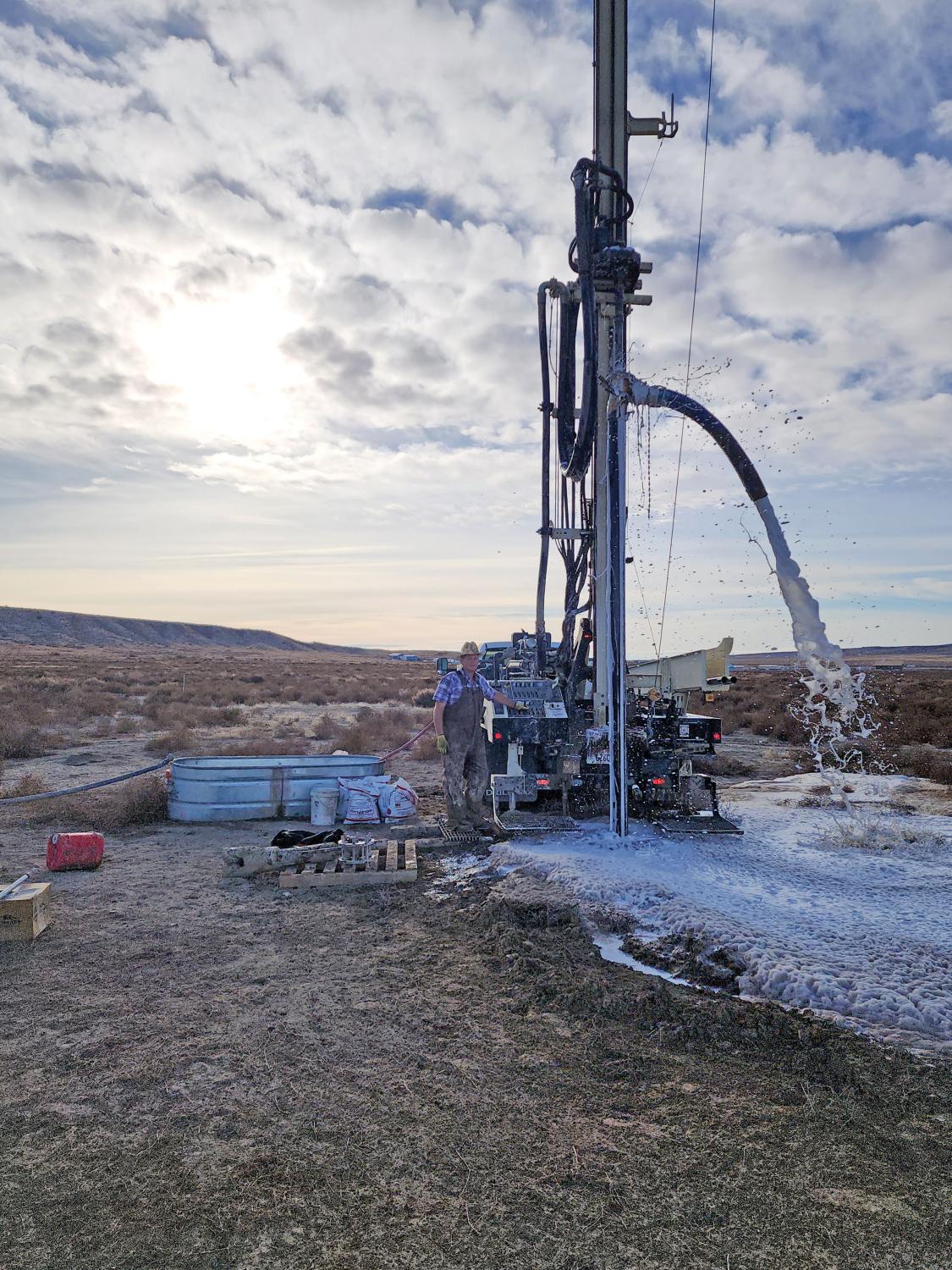

Whether in wide-open spaces or tucked between boulders and canals, the DM250 provides power and lift to clear gravel geology.

While Douglas Higley’s family tree included well drillers, it was actually a family disagreement that led him to launch Higley Oasis Waterworks in Utah.

“As a well driller and farmer, my grandfather drilled six irrigation wells free-flowing water to my property 4-miles away,” Higley explained. “As can happen, disagreements among family developed regarding who should get the water. So an offer was made to pay to have a new well and pump drilled on my property.”

As he was working through transferring the water rights, Higley struggled to find anyone to drill the well. The state engineer advised him to get his drilling license and become a well driller.

“I worked as a diesel mechanic for 26 years, but three years ago I passed the driller's licensing tests and drilled an 8-inch, 350-feet deep well, providing 400 gallons per minute,” Higley said. “Then I drilled a second 8-inch well, 600-feet deep.”

However, the constant stream of drilling profits being funneled back into repairing his aging equipment prompted him to explore new rigs.

“I considered a couple of options, but I liked how small the DM250 is and that it could still do 500-foot holes,” Higley said. “I also wanted 20-foot tooling, and the other option I considered had 10-foot tooling.”

Higley’s decision was confirmed after making the trek to a DM250 demonstration in Kansas.

“I’d never seen a well drilled that quickly,” he said. “It might be better to have a bigger rig because of the depths I’m drilling, but the DM250 is doing it pretty well.”

On a job in the mountains of Northern Utah with limestone rock, boulders, and gravel, Higley was able to install a 6-inch well, 200-feet deep within two days.

“It was next to a canal and near boulders, so any bigger rig wouldn’t have been able to access where the owner wanted the well,” he said.

The torque of the gearbox on the head has surprised Higley. He’s also impressed by the ability of the 125 cfm air compressor’s ability to lift 1.5- to 2-inch rocks out of the hole for 200 feet.

“When using pre-perforated pipe with air and foam, I can run steel casing through rock, boulder, gravel geology to complete a 200-foot hole,” Higley said. “It may be a little machine, but it’s a workhorse.”

Higley appreciates the easy operation with accessible controls to simplify switching between air and mud and amplify its versatility. He also appreciates the 4-wheel drive allowing him to get into places without tearing up the property.

“I'm more mobile versus transporting my older rigs,” he said.

With the DM250 he no longer pours his hard-earned resources into repairs, but rather knows he can rely on Geoprobe® for his parts needs.

“The rigs are put together well and the team has the experience needed to guide you in the right direction,” Higley said. “They’re great people who always have parts in stock and get back to you in a timely manner when you call.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date:

Related Videos

DM Water Well Rig Series Overview

ID: 14052

Geoprobe® Walkaround: DM650 Air Rig

ID: 14045

ID: 14042

ID: 14040