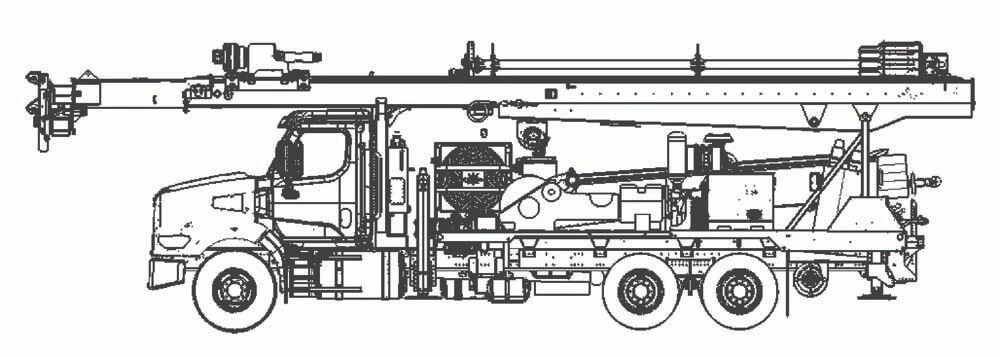

DM650 can be outfitted for air drilling vs mud drilling depending upon preference for drilling wells in your area.

Growth east of home base in Burnet, Texas, has Robbie Barnard owner of J&J Water Well & Windmill Services increasingly concerned whether he's equipped for success drilling the necessary 1,000-foot deep wells.

“My main concern is the rig I have now can’t handle those depths, and I don’t want to lose out on the business,” Barnard said. “So the DM650 capabilities caught my eye and its similar operation to my current rig means I wouldn’t have a huge learning curve.”

Barnard perched on the DM650 at the National Ground Water Association (NGWA) show in Las Vegas last December for an hour taking in every inch of the new rig.

“What impressed me most was the engineers stuck to what has proven to work — manual controls,” Barnard said. “Manual valves mean not much to go wrong and you have the ability to stay safe and confident it will work.”

He appreciates the DM450 and DM650 share a similar simple control center with everything within reach in front of you.

“The controls on the helper side and extra rack for them to stand on is also an impressive addition,” Barnard said.

He was also impressed by the attention to detail engineers placed on simplifying fieldwork.

“The way they built the breakout wrench caught my eye. They actually put handles on it. It’s the little luxuries that make our day easier,” Barnard said. “I looked at all the rigs there and the routing of the plumbing and hoses on the DM650 are very clean. They were in unison, mostly to always hidden, and were straight, narrow, and looked good.”

Mark Kelly of Emerald Coast in Alabama also appreciated the clean routing of hydraulic hoses when he saw it at the NGWA show.

“Man, I love the DM650. It looks like it’s built well,” Kelly said. “I appreciate the design of the new mud pump and the amount of power it has. It’s a very nice, heavy-duty machine.”

Kelly believes it would help him get a lot more of his 4- to 12-inch domestic farm and sprinkler pivot wells completed.

“It’s much faster, heavier, and has more pull down,” Kelly said. “I could do jobs a lot faster.”

Other features catching drillers' eyes include:

- Ample power, both on and off the road

- Increased speed and efficiency running multiple functions without losing hydraulic power

- Speed and labor savings of the rod carousel

Mario D’Agostino admits he prefers a little extra when it comes to rig size for his New Jersey D’Agostino Well & Water Services. To him, the DM650 hits the mark.

“It looks well engineered with everything in the right spot,” D’Agostino said. “It’s probably bigger than I need, but if I bought a new rig, it would be what I want.”

Setup for Air Drilling vs Mud Drilling when Drilling Wells

Air Drilling: Down-the-hole hammer setup with up to 1070 CFM/350 PSI air compressor

Mud Drilling: Setup with 6X8 piston pump along with a 4X3 centrifugal pump with ability to run either pump independently or supercharge piston with the 4X3

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Rig service technicians work quickly to make precise repairs, knowing downtime affects the business.

ID: 14622 | Date:

Service technicians offer onsite repairs or over the phone troubleshooting.

ID: 14621 | Date:

With dual centrifugal pumps and the ability to upream, DM650 has power and speed to tackle deep western Kansas wells.

ID: 14594 | Date:

DM650 pipe handling and backloading carousel make big-diameter wells faster, easier, and safer for crews.

ID: 14593 | Date:

From one rig to two in less than a year, DM250 holdback and carousel help keep Texas-based water well business running fast and efficient.

ID: 14591 | Date:

Related Videos

DM Water Well Rig Series Overview

ID: 14052

Geoprobe® Walkaround: DM650 Air Rig

ID: 14045

ID: 14042

ID: 14040

ID: 13965