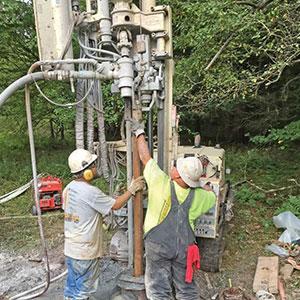

Cory Walker is starting up his own company, CORTEK Drilling in Nashville, TN, with a Geoprobe® 7822DT. Cory, his wife, Lindsey, and the handsome 3-1/2 -year-old German Shorthair, Buddy, stopped in Kansas to see their new machine before it was delivered. He and his driller returned two weeks later for machine and maintenance training.

One of our most versatile machines just got an efficiency boost! A true dual winch option is now available for the 7822DT. With the primary winch providing 2,600 pounds of pull and the secondary winch operating at 220 ft/min, drillers now have access to the speed and depth capacity of a wireline without losing the pullback of the main line.

Operators of machines set up for extended rock coring will immediately recognize the benefits of a secondary winch dedicated to wireline work. However, a dual winch arrangement is also beneficial for multi-purpose machines that may not core rock every day. Victor Rotonda, Geoprobe® Sales, identified one of the biggest assets of the dual winch kit. “The drilling industry is accustomed to having two winches on a rig,” he said. “When some drillers see a machine with only one winch, they say, ‘This is going to be a chore. I have to change out the wire rope if I get a geotech job.’ Now they have the option of adding the secondary winch when purchasing the machine and are ready if a geotech job comes up.”

Cory Walker, of CORTEK Drilling in Nashville, TN, chose the dual winch setup for his new 7822DT machine as he starts his new company. Cory explained: “The decision to purchase the secondary winch was based on the geologic conditions present in our area. Shallow refusal can be common.That, coupled with a high potential for voids and karst activity within the bedrock, warrants the need for confirmatory rock coring. Having a dedicated wireline winch will allow us to core efficiently, saving both time and money for our clients.”

Quick Change Hook and Overshot Clevis

Perhaps the handiest feature of the dual winch kit is the method of attaching accessories to the wire rope of the secondary winch. When ready to switch to coring, simply swap out the quick change swivel hook for the overshot, and continue working. It’s quick, it’s simple, and can all be done by hand.

Both winches leave the factory equipped with swivel hooks. But while the swivel hook of the primary winch is permanently affixed, the wire rope of the secondary winch incorporates a quick-change mechanism that allows switching between the swivel hook and a supplied overshot clevis – no tools required. Simply unthread the retainer cap, move the end of the wire rope from the slot in the quick change swivel hook to the slot in the quick change overshot clevis, and retighten the retainer cap.

3-foot Winch Mast Extension

For maximum efficiency when coring, outfit your new 7822DT machine with the optional 3-foot mast extension to complement the dual winch setup. The winch mast extension gives the added reach needed to easily clear the top of the tool string when retrieving the overshot and core barrel.

Call us for more information!

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

As a project engineer with a Ph.D., Aaron Crowley desired to own his own company. So in May 2022 he partnered with Julie Oliphant, owner of Athena Engineering and Environmental, to launch a sister company ATHENA DRILLING to complete a range of geotechnica

ID: 13413 | Date:

For some air rotary drilling is a rarity, but for EICHELBERGERS INC in Pennsylvania it’s a weekly occurrence using their 7822DTs. They’ve completed air rotary to 220 feet; they’ve drilled using 8-inch and 10-inch casing. On one project they set 10-inch ca

ID: 13412 | Date:

Starting his drilling industry career as a consultant, David Draybuck discovered he didn’t love writing reports. So in 2011, he and his partner gathered funds from closed 401(k)s and an SBA loan to buy a piece of used equipment and launch ENVIROTECH DRILL

ID: 13409 | Date:

Established in 2017 to provide drilling services to geotechnical engineers — focusing on mud rotary technology, PG ENVIRONMENTAL SERVICES struggled to break into the environmental market.

ID: 13407 | Date:

Passionate about delivering exceptional geotechnical, environmental, and instrumentation exploration services, the TERRACON CONSULTANTS INC office in Savannah, Georgia, went from being without in-house drilling resources in 2021 to running three Geoprobe®

ID: 13403 | Date: