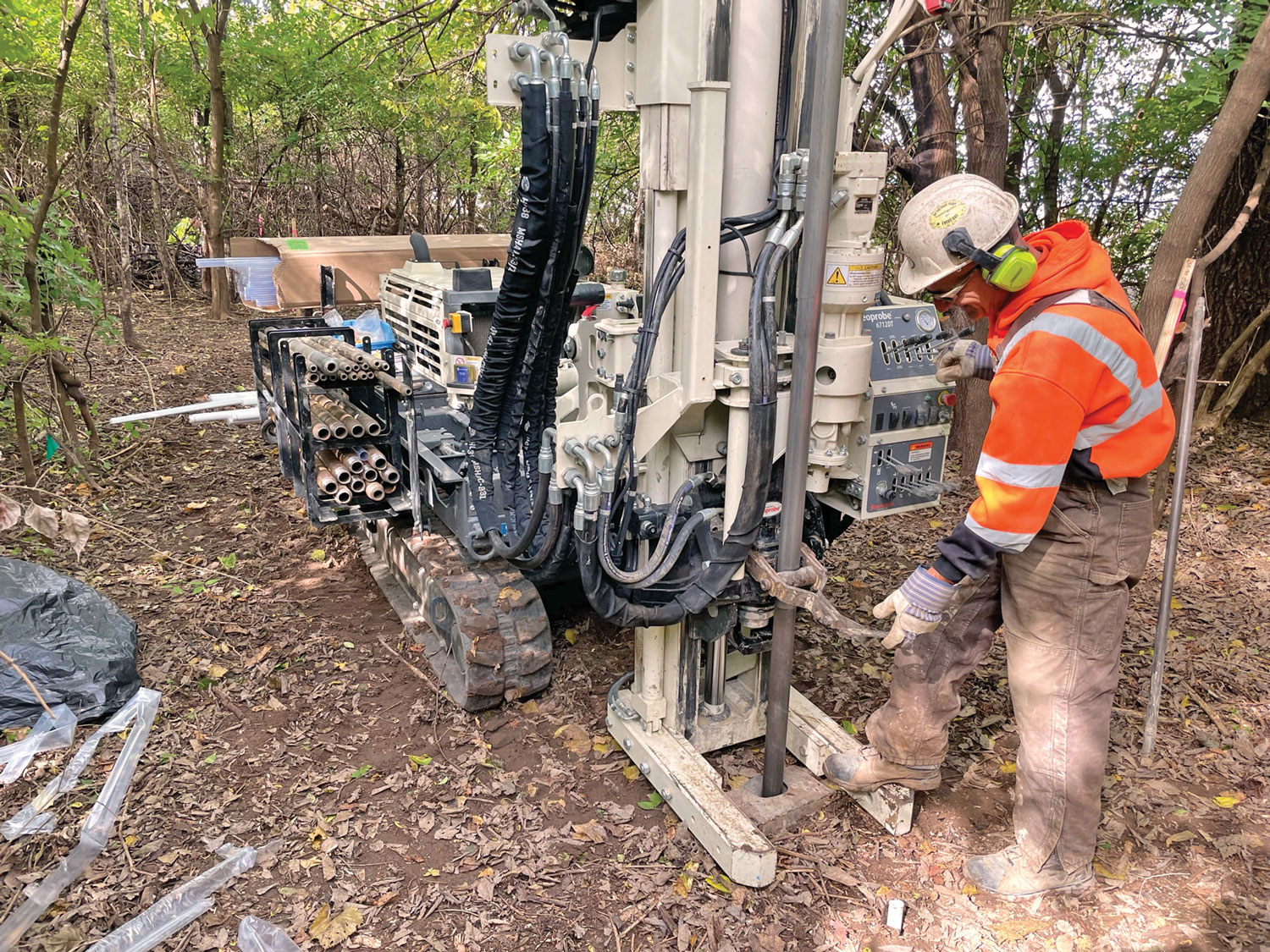

Direct push power and limited augering ability of new 6712DT means taking it out on tougher jobs previously reserved for the 7822DT, including 2-inch prepack groundwater monitoring wells.

Providing traditional environmental probing and sampling services, Rob Mores, owner/operator, characterizes Enviro Dynamics in Indiana as a small company. Their four field employees use their three drill rigs — two 6712DTs and one 7822DT — to provide consistent services for the past 25 years while their capabilities to do bigger projects and wells have grown as Geoprobe® has grown.

“In the 1990s we were using 5400s just doing direct push, 1-inch wells. As we got into the larger GH60 hammers and augers, we now have more capabilities within our service range,” Mores said. “We developed as Geoprobe® developed bigger, more powerful machines.”

Wanting to stay smaller and work within the environmental niche, they focus on the most commonly required work.

“Our goal was to focus on services that the equipment we have can do on an everyday basis. We didn’t want to buy equipment we’d use once or twice a month,” Mores said. “We didn’t want to grow to have a lot of people who have to specialize.”

They bought their first 6712DT in 2014 and added a second in 2017. Then after attending the 2021 Geoprobe® Open House and witnessing the improvements on the 6712DT Stage V — including the machine horsepower, he eventually sold his 2014 6712DT and bought the new 6712DT.

“There’s a noticeable power difference in driving rods. The new 6712DT doesn’t work as hard to do the same amount of work,” Mores said. “The bigger engine requires less strain than the smaller engine.”

Within a week of getting the new 6712DT, they installed three 2-inch prepack groundwater monitoring wells with 3.75-inch probe rods to 25 feet.

“We had the 7822DT on standby, but the 6712DT performed well,” Mores said. “We could definitely notice a difference in the hammering capabilities between the newer and older 6712DT.”

They have now completed a half-dozen jobs installing prepack groundwater wells with 2-inch casing 20 to 30 feet.

“For us, 60 to 70 percent of our work is direct push and the 6712DT has proven to get done what we need to get done,” Mores said. “The 6712DT gets depths we need and drives rods.”

Other advantages include the option of a wireless remote, the electronic versus mechanical throttle eliminating freezing up during temperatures below 25, and the addition of the display for onboard diagnostics and performance readings. He also appreciates the compact size amplifying job site access and simplifying transportation.

“We do a lot of work in Chicago and suburbs where space is at a premium,” Mores said. “It’s lighter so it’s easier to trailer and we can stay under CDL requirements.”

With the new 6712DT they can schedule jobs in tougher probing conditions where they would have otherwise sent the 7822DT.

“We’re willing to try tougher jobs out with the new 6712DT, which means we’re able to get to jobs faster,” Mores said. “We now send the 7822DT primarily to do augering and if we need a second rig we use the new 6712DT with more engine horsepower, more hydraulic power, and a more powerful rotary motor.”

They’ve still retained their 6712DT with low-clearance cylinder, which he describes as being “invaluable”.

“Lots of jobs have a 9- to 11-foot overhead clearance. The 6712DT LC has allowed us to do a lot of projects that may have been done with hand equipment, but the LC could definitely get in there,” Mores said.

Overall, they’re glad they made the investment in upgrading to the newer version 6712DT.

“For an operator or company looking for a smaller direct push platform because they predominantly do direct push and limited hollow stem augers, then you don’t need the extra weight and size of a 7822DT,” Mores said. “The new 6712DT provides relatively similar direct push results in an economical package.”

Adding to the value of the 6712DT are the Geoprobe® reliability, dependability, and customer service.

“Nobody can compete with the service and reliability. Typically I’ve been able to resolve mechanical problems in the field by calling service. Most times, the guys have the ability to walk people who aren’t even technically strong through problems,” Mores said. “I’ll never buy anything from anyone else.”

The dependability extends to Geoprobe® tooling as well.

“I have a good network of guys who run companies like mine, and I talk to people who buy tooling from other manufacturers and their tooling doesn’t last as long,” Mores said.

He attributes Geoprobe® for growing the overall technology of the environmental industry when it comes to subsurface investigation.

“I can’t expound enough how much Geoprobe® has driven the environmental industry to grow and be successful. They’ve pushed companies to be better. It’s amazing what they’ve developed in a little more than 30 years,” Mores said. “It’s a complimentary relationship. They’ve always been there and had the tools and equipment I need to be successful.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

Focused on vapor intrusion, H&P MOBILE GEOCHEMISTRY is one of few companies in their region of California to offer a one-stop-shop for completing vapor probe installation, soil gas sampling, and analyses.

ID: 13418 | Date:

Primarily roaming within a 100-mile radius of Philadelphia, TRISTATE ENVIRONMENTAL MANAGEMENT SERVICES performs a broad range of environmental field services in New Jersey and Southeast Pennsylvania. Project Manager Ted Sobieski credits their “jack-of-all

ID: 13417 | Date:

In the environmental drilling industry for two decades, Scott Densteadt has seen it come full circle. “When I started, all we did was drill hollow stem auger or mud rotary. Then direct push side of things really took off and became the standard. However,

ID: 13415 | Date:

GEOTEK ALASKA began with a 54DT and environmental drilling as their bread and butter. Through the years the Alaska company has diversified by opening a second location — in Hawaii — and completing a 50/50 mix of environmental and geotechnical drilling. As

ID: 13414 | Date:

For some air rotary drilling is a rarity, but for EICHELBERGERS INC in Pennsylvania it’s a weekly occurrence using their 7822DTs. They’ve completed air rotary to 220 feet; they’ve drilled using 8-inch and 10-inch casing. On one project they set 10-inch ca

ID: 13412 | Date:

Related Videos

ID: 13740

3230DT Walkaround - Control Panel

ID: 13627

ID: 13626

Geoprobe® MD4 Display Overview

ID: 13461

ID: 12781

ID: 12726