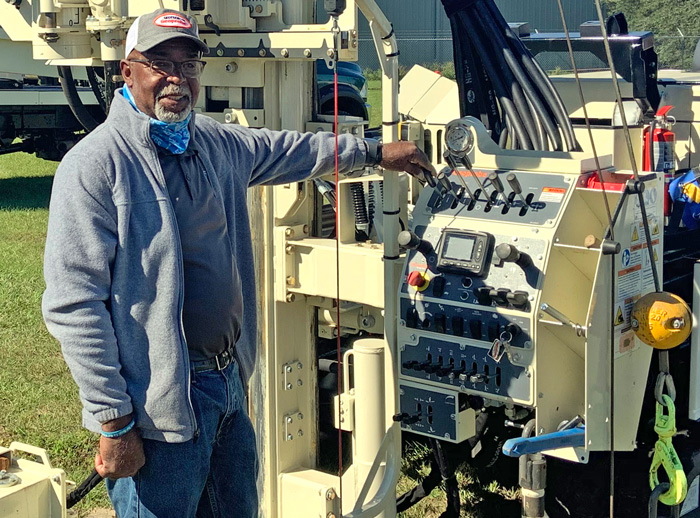

The numerous advancements on the 3100GT compared to their 4-year-old Geoprobe® reinforced the value of Geoprobe® for geotech work for TTL Associates operations manager Rick Mielcarek

Doing a bit of everything in the private and government sectors - including drilling, environmental, geotechnical engineering, and construction materials testing - the 100-year-old TTL Associates out of Ohio was eager for the opportunity to review a couple of Geoprobe® machines at a tools-in-the-ground demonstration outside Indianapolis as well as the opportunity to talk about new technologies.

“Always seems Geoprobe® listens to clients and has their ears open,” Rick Mielcarek, operations manager, said. “They come up with innovative ideas by listening to people using the machines, coming up with solutions, and putting them into place.”

Having paid attention to information coming out about the 3100GT and CPT, he was eager to see and better understand how it functions.

“It blows my mind the amount of modifications on the new rig compared to our 4-year old rig. The way you can move the head. The measurement stick on the drop hammer,” Mielcarek said. “Simple stuff that other drill rig manufacturers have known we need but Geoprobe® figured out a way to make it happen.”

As a heavy geotechnical company, in the past it had sometimes been difficult to convince leadership how Geoprobe ® could benefit the vast majority of the company’s geotechnical work.

“Over the years TTL has come to understand that Geoprobe® is not a fad and continues to become a bigger player in our world,” Mielcarek said. “It’s cool to see Geoprobe® isn’t just an environmental type of machine anymore and are specializing in producing machines to handle geotechnical types of applications.”

Others who attended demonstrations in Indiana and Florida are also coming to realize the various ways the NEW 3126GT and 3100GT can help advance their geotechnical business.

POWER KEY FOR DLZ

Specializing in doing the hard stuff no one else wants, DLZ Ohio out of Columbus is a turnkey engineering firm completing large infrastructure, government buildings, highways, commercial power facilities, tunnels, dams, and levees projects.

“Most of our work is for federal, state, and local governments and related to agencies like the Army Corps of Engineers, as well as smaller projects for other engineering firms,” Brian Mott, environmental specialist, said.

Attending the tools-in-the-ground demo in Indiana provided the opportunity for members of their drilling group to run the machines.

“It gave them the chance to see how the Geoprobe® operation was similar, and in my opinion, easier to operate than the typical auger-style rig we usually use,” Mott said. “The level of sophistication and ability to do more was good to see in person. It’s not just a direct push machine anymore, it’s much more powerful.”

Favorite features included:

- Dual hydraulic pumps

- Low footprint for tight spaces

- Ability to articulate the mast for drilling, useful in more difficult areas

“We get called on a lot to do direct push work and CPT work in the Great Lakes region,” Mott said. “This distinct need by clients pushed us to get another Geoprobe® for the first time in 20 years, but it comes with the ability to do CPT and other things besides direct push, including augers and mud rotary.”

This versatility gives them the ability to use the rig continuously versus a standalone CPT rig that would be used and then parked for long periods between uses.

“This will mean we will see a faster return on our significant investment in the machine because we are not buying a single-use tool such as a standalone CPT or DP machine,” Mott said.

Mott anticipates drillers will want to use the 3126GT over their big conventional rigs for a lot of jobs.

“Our drilling supervisor was impressed by the amount of power the 3126GT had. He anticipated something less powerful for the package size,” he said. “It’s easy to use and can handle 50 percent of the work we do – other than the deep borings in the hard tills and very dense sands and gravels in the glaciated areas below the Great Lakes.”

CONTROL TOPS FOR ALT & WITZIG ENGINEERING

Headquartered near Indianapolis, Alt & Witzig Engineering primarily completes pre-construction work for commercial projects, some industrial, and DOT. Having attended the 3126GT virtual live demonstration, Dave Harness, project manager, had some lingering questions.

“I was looking forward to seeing the 3126GT because Geoprobe® keeps refining and improving their geotech offerings. I was interested in the usability of the 3126GT. There’s been a shift in available drilling staff and what they’re willing to run as well as safety protocols,” Harness said. “It’s similar to previous renditions of drilling rigs we had, but I like this one because it minimizes moving parts on the head. It has enough engineering to keep drillers out of harms way.”

Keeping an eye toward expanding services, Harness appreciated the platform’s ability to do a little bit of everything with one rig – including CPT.

“The rig has a lot of push/pull capacity but also a lot of control. The hydraulic lever handles we’re used to versus the display and ability to tune controls on the 3126GT control panel is way, way ahead of other drilling rigs,” Harness said. “How they’ve worked out the operating system impressed me more than anything. They took care of all the little details to make things easier in the field.”

For Harness, this provides an opportunity to limit subcontracting work.

“We have an older Geoprobe® and do subcontract to those who have bigger Geoprobe® models,” he said. “Previously Geoprobe® just pushed soil samples, but now it can go and economically and effectively core concrete and rock. This would limit our need to subcontract.”

Having come to expect professionalism – even perfectionism – from Geoprobe®, the 3126GT did not disappoint.

“This rig is better suited for the mindset of today’s field crews,” he said. “It’s a safer option than other rigs.”

SAFETY IMPRESSES AMDRILL

The versatility of the 3126GT to handle all three types of drilling drove Amdrill to attend the demonstration in Ocala, Florida.

“When you hear Geoprobe® you generally think DPT or CPT not SPT, but that 3126GT is definitely capable of it – as are most Geoprobe® rigs,” Todd Ives, operator, said.

Taking input from drillers, the 3126GT has the finishing touches to make fieldwork easier.

“The rig is put together very well. Lot of thought was put into it – every piece of real estate is utilized well. From little cubbies near the control panel, tables for cutting liners, hooks and hangers for tools,” said Ives. “The CPT box integrated into the rig so you can put your module in there, shut and lock the door, and know it’s protected is a nice touch.”

These considerations also caught the eye of safety manager Tanner Clarkson.

“Providing lots of places for tool storage helps with housekeeping. We do a number of jobs on the side of the road, so the housekeeping of tools becomes critical,” Clarkson said. “When we first opened our Brooksville location we shared a shop with a welding company. There wasn’t a day that a driller wasn’t coming in and asking one of the welders to add a storage compartment somewhere. Now they’re already on the rig.”

Other critical components stood out to Clarkson.

“There were a lot of details that are generally overlooked – like the indicator to line up the head when sliding between functions,” Clarkson said. “This is especially important when you’re in a rush and eyeballing it makes for a crooked hole.”

With fewer rotating parts and various staging parameters, Clarkson anticipates the increased safety would equate to efficiency when working on Mosiac mines.

“We do jobs on Mosaic mines, which are strict about what equipment can go in and do work. Conventional rigs sometimes are not allowed because of inadequate safety guards,” Clarkson said. “The way the 3126GT is designed would cut down on the inspection time required to get into Mosaic mines making it easier to get in and do the job.”

The efficiency of the rig and potential for increased productivity also piqued Ives’ interest.

“Whether you’re looking to use it on multiple types of job sites or to offer more services, the 3126GT isn’t a huge rig – but it’s big enough,” Ives said. “And it’s fairly priced for all you’re getting.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Photo Gallery

Related Articles

Engineers who had gained valuable geotechnical experience working for the US Army Corps of Engineers Vicksburg District and the Waterways Experiment Station in Vicksburg, Mississippi, launched BURNS COOLEY DENNIS in 1985. Now with a staff of more than 60,

ID: 13399 | Date:

Established in 2004 as a strictly environmental services company, DIRECT PUSH SERVICES has expanded from a couple of rigs and two employees to six rigs and 15 employees. During the past five years, the Utah company has realized this expansion through the

ID: 13398 | Date:

Since launching G2 CONSULTING GROUP in 1994, the Michigan company has outsourced drilling for its geotechnical and environmental consulting and materials testing services. However, during the past few years, drillers they’d been using began discontinuing

ID: 13397 | Date:

Tri State Drilling LLC operates 10 rigs on a daily basis providing environmental, geotechnical, and mineral exploration drilling services for engineering firms across the southeast from their offices in Chattanooga and Nashville, Tennessee. Four of their

ID: 13150 | Date:

Related Videos

ID: 13740

Geoprobe® MD4 Display Overview

ID: 13461

ID: 13394

ID: 13370

Geoprobe® - 31 Series Overview

ID: 6658

ID: 5533

ID: 268

3100GT PTO Engagement Instructions

ID: 6521