The ability to shift your scope of services raises resiliency to downturns in demand. Having a combination rig like the 7822DT provides the versatility to pivot in response to restrictions or economy without sacrificing power or production. Geo Lab Probing Services uses their 7822DT to even the playing ground dominated by conventional rigs.

Establishing a strong foothold in the direct push business, Geo Lab Probing Services got their start in 1996 as a sampling, on-site lab screening company using a probe in a van – which included their chemistry lab. Since then they’ve sought ways to stretch their capabilities.

“We purchased conventional drill rigs to broaden our scope of services beyond direct push, only to realize that 7822DT rigs are often preferred for conventional drilling tasks due to their efficiency and mobility,” Strickland said.

All the development in Georgia keeps Geo Lab busy completing geotech investigations which often involve shallow SPT borings to rock with automatic drop hammer, split spoon blow counts until auger refusal, and then switching to NQ wireline for 10 to 15 feet of rock core confirmation.

“The 7822DT is very efficient and outperforming conventional rigs head-to-head. It’s not cumbersome to complete 80 to 100 feet in a day. We’re not showing up as second best against a conventional rig,” Strickland said. “In a playground dominated by conventional drill rigs, we can come in and show them that Geoprobe® core rock. The efficiency gained allows us to do more linear footage and play ball with the big dogs, and we don’t have to concede on rates or production.”

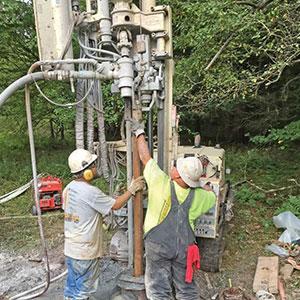

Similarly, Enviroprobe Integrated Solutions in West Virginia has steadily increased its geotechnical work. Now 70 percent is geotechnical. For Jim Fore, operator, his preferred rig is the Geoprobe® 7822DT.

“The Geoprobe® 7822DT does as much geotechnical work as our conventional rigs do,” Fore said. “It’s a stout rig with growing technology. It’s tough. There are no issues hammering or pulling DT45 steel. And the coring speed is just as fast as other rigs on the market.”

As their field of work has changed over time, Fore leverages the 7822DT’s ability to core rock. He’s run HQ casing to advance more than 160-feet into mine refuse and boulder fill while SPT sampling before continuing to rock core to 225 feet. He’s reached 247 feet below ground surface rock coring in Pennsylvania.

“We have the most overworked rigs, but we’ve had our second 7822DT for more than two years with no breakdowns,” Fore said.

GeoTek Hawaii’s 7822DT weaves its way into clusters of structures to complete urban investigations. In tight, rough conditions the rig completed 175-foot HQ rock core.

“We can advance SWT 6-5/8-inch casing that bigger machines can’t handle in their breakout clamps,” Quinton Wilson, operations manager, said. “And the 4-speed head has nice torque-speed settings. It does well spinning H core as well as utilizing solid flight augers.”

Their ability to maneuver under trees, into tight alleys, and alongside drifting houses has allowed them to conduct more work and allowed their clients to become more creative with preliminary site investigations completed before demolition.

“They can see the feasibility of a project in a less intrusive manner before paying for building permits,” Wilson said.

Geo Lab’s success includes running split spoons under gas station canopies and traversing undeveloped land only crafting simple makeshift bridges over creeks.

“Most conventional rigs can’t perform low-clearance work under canopies and inside buildings with the nimbleness of a 7822DT,” Strickland said. “We have the ability to respond across the board. Name the project and we have a distinct advantage if we can find the unique tool to do it. We know we have the rig and the operator, which gives us more access and impresses customers.”

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Articles

As a project engineer with a Ph.D., Aaron Crowley desired to own his own company. So in May 2022 he partnered with Julie Oliphant, owner of Athena Engineering and Environmental, to launch a sister company ATHENA DRILLING to complete a range of geotechnica

ID: 13413 | Date:

For some air rotary drilling is a rarity, but for EICHELBERGERS INC in Pennsylvania it’s a weekly occurrence using their 7822DTs. They’ve completed air rotary to 220 feet; they’ve drilled using 8-inch and 10-inch casing. On one project they set 10-inch ca

ID: 13412 | Date:

Starting his drilling industry career as a consultant, David Draybuck discovered he didn’t love writing reports. So in 2011, he and his partner gathered funds from closed 401(k)s and an SBA loan to buy a piece of used equipment and launch ENVIROTECH DRILL

ID: 13409 | Date:

Established in 2017 to provide drilling services to geotechnical engineers — focusing on mud rotary technology, PG ENVIRONMENTAL SERVICES struggled to break into the environmental market.

ID: 13407 | Date:

Passionate about delivering exceptional geotechnical, environmental, and instrumentation exploration services, the TERRACON CONSULTANTS INC office in Savannah, Georgia, went from being without in-house drilling resources in 2021 to running three Geoprobe®

ID: 13403 | Date: