6712DT Drill Rig

Video: Geoprobe® 6712DT Overview

Flexible Mobilization through Modular Design

Drillers seeking a lightweight, small drilling rig choose the 6712DT for their small to medium direct push projects. Designed in three components, the small drilling rig can be air lifted to remote mountain tops or into cavernous structures. Despite being a small drilling rig, the 6712DT packs the power to do shallow augering, increasing the amount of drilling operations completed in-house. Companies depend on the 6712DT to:

- Complete multiple functions with a single rig, reducing dependency on other drillers

- Provide small footprint and modular design, mobilizing into tight spaces or remote locations

- Leverage simple, straight-forward operations, increasing productivity

Owners appreciate their ability to reduce rescheduling jobs thanks to the multi-functional small drilling rig. Taking your business to the next level is easier with the 6712DT small drilling rig.

Features & Options

6712DT small drilling rig with Tier 4 engine provides additional controls and additional engine monitoring display on the screen for easy operation

Owners expanding their drilling capabilities choose the 6712DT small drilling rig to increase depths of both augering and direct push.

The latest Tier 4 6712DT features a host of enhancements:

- additional power

- additional electronic controls, like the throttle rocker switch, for easier operation and tracking

- additional engine monitoring now displayed on screen eases operation and increases safety

Reducing rig limitations with the 6712DT keeps drillers booked out consistently while an array of features and options tailors the small drilling rig to their needs, including:

- Modular machine design can be assembled and disassembled in three parts (pick weight under 2,000 lb per component)

- Drill mast with 36,000-lbf push, 48,000-lbf pull, and optional sideshift

- Simple hydraulic design

- Heavy-duty track drive system

- GH63 Hammer w/ single speed Bi-directional rotation, modular percussion power cell technology

- Simple control panel design, manual controls provide tactile feel

- Optional GA2500 two-speed rotary head (2,500 ft/lb, up to 150 rpm)

- Optional mast & winch system (2,500-lbf winch)

- Rear blade assembly for tooling transport and machine stabilization

- Better access to key components for serviceability and maintenance

- Wireless (optional feature) and tethered remote drive

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your small drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new small drilling rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Features & Options

Owners expanding their drilling capabilities choose the 6712DT small drilling rig to increase depths of both augering and direct push.

The latest Tier 4 6712DT features a host of enhancements:

- additional power

- additional electronic controls, like the throttle rocker switch, for easier operation and tracking

- additional engine monitoring now displayed on screen eases operation and increases safety

Reducing rig limitations with the 6712DT keeps drillers booked out consistently while an array of features and options tailors the small drilling rig to their needs, including:

- Modular machine design can be assembled and disassembled in three parts (pick weight under 2,000 lb per component)

- Drill mast with 36,000-lbf push, 48,000-lbf pull, and optional sideshift

- Simple hydraulic design

- Heavy-duty track drive system

- GH63 Hammer w/ single speed Bi-directional rotation, modular percussion power cell technology

- Simple control panel design, manual controls provide tactile feel

- Optional GA2500 two-speed rotary head (2,500 ft/lb, up to 150 rpm)

- Optional mast & winch system (2,500-lbf winch)

- Rear blade assembly for tooling transport and machine stabilization

- Better access to key components for serviceability and maintenance

- Wireless (optional feature) and tethered remote drive

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your small drilling rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new small drilling rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

“If we know the site condition, we can bring the 6712DT and not sub out as much, which means more profit. I don’t have to go back to the site. I don’t have to reschedule. It reduces my limitations, and I’m booked out consistently.”

- Don Kellar, CEO, Fulcrum Resources Environmental, California

Tooling & Accessories

Video: DT22 Soil Sampling System Overview

The Geoprobe® DT22 Soil Sampling System is a direct push system for collecting continuous core samples of unconsolidated materials from within a sealed casing of Geoprobe® 2.25- inch outside diameter probe rods. Samples are collected and retrieved within a liner that is threaded onto the leading end of a string of Geoprobe® 1.25-inch OD light-weight center rods and are inserted to the bottom of the outer casing.

The DT37 Soil Sampling System, designed for use with 3.75-inch probe rods, uses a unique combination of the cutting shoe, sheath, and liner retainer to allow efficient recovery of samples in formations ranging from plastic clays to saturated sands. The DT37 system is designed to quickly recover samples well below the water table. Problems with liner failure or having the liner lodge in sample sheath are virtually eliminated with this system.

Video: SP22-ISP Groundwater Sampler

The Screen Point 22 (SP22) Groundwater Sampler from Geoprobe Systems® was designed to keep the screen away from all percussive energy while the sampler is lowered downhole, thus extending the life of the screen.The SP22 can be used alone as a groundwater grab sampler or groundwater profiling tool, or with the DT22 Soil Sampling System. The screens can be deployed using either 1.25-inch Lightweight Center Rods or PVC riser.Designed for tough probing conditions, the screen head on the fully retrievable sampler adapts to either a stainless steel or PVC screen.

Video: Geoprobe® Macro-Core® Center Rod

Our MC5 Soil Sampling System is a single tube, discrete or continuous system with unmatched durability.MC5 Light Weight Center Rod Soil Sampling System. The MC5 1.25-inch Center Rod System was designed for the absolute worst of the worst direct push probing conditions. “These are conditions that we normally do not recommend probing in,” according to Mike Carlin, Project Engineer, “so we developed the toughest soil sampling system in the direct push industry ... it’s a brute!”Macro-Core® is a registered trademark of Kejr, Inc., Salina, KS.

Video: Interlocking Split Spoon Overview

Engineered to be stronger, last longer, and save money and time, the patented interlocking split spoon meets ASTM Standard D1586.The finger-like design self aligns, creating a perfect fit and quicker assembly. With the threads aligned, the cutting shoe and drive head can be threaded to the split spoon. Multi-lead threads require fewer turns during assembly and disassembly over conventional split spoons, speeding up each test interval.In additional to time savings, enhanced material properties and manufacturing result in greater longevity. Each interlocking point keeps the two tube halves engaged throughout the sampling process. The strength of these connections prevents the sampler from bulging in dense materials. It also keeps the tube halves tightly engaged even when over-filling of the sampler occurs.

Video: Geoprobe® Hydraulic Liner Extruder

This tool sure makes life easier in the field. In the middle of a busy day, you don’t need the hassles associated with a stubborn, stuck liner. The Geoprobe® Hydraulic Liner Extruder is simple to use and can be adapted to most Geoprobe® machines with auxiliary hydraulics. A two-piece adapter converts the extruder assembly to accommodate larger diameter DT325 sample tubes. Using the Hydraulic Liner Extruder is simple. A Macro-Core®, DT22, DT325, or DT45 Sample Tube with the sluggish liner is threaded on to the front end of the extruder. As the hydraulic "push" is applied to the opposite end of the extruder, the liner is slowly pushed from inside the Sample Tube and out the end of the extruder. Macro-Core® is a registered trademark of Kejr, Inc., Salina, KS.

Applications

Videos

Specs

Specifications are subject to change without notice.

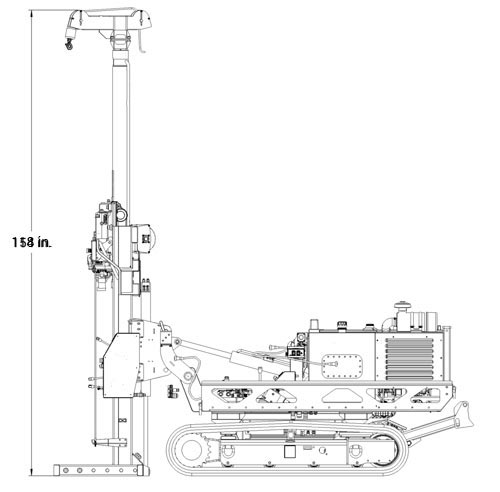

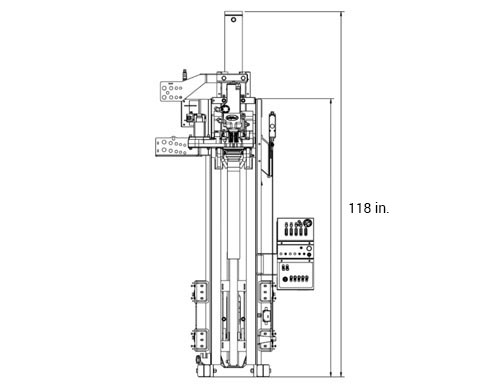

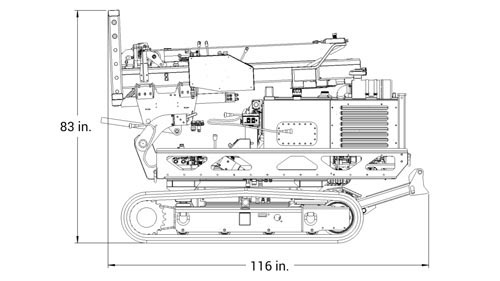

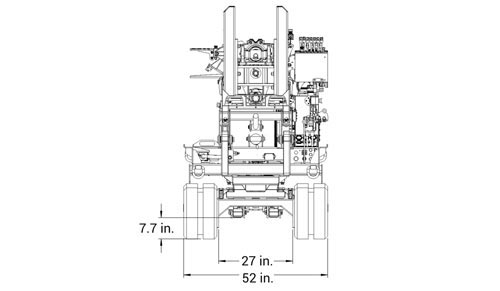

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 52 | Width (mm) | 1,321 |

| Length (transport) (in) | 116 | Length (transport) (mm) | 2,946 |

| Length (deployed, lateral fully extended) (in) | 167 | Length (deployed, lateral fully retracted) (mm) | 4,242 |

| Height (normal transport) (in) | 83 | Height (normal transport) (mm) | 2,108 |

| Height (deployed; Head up) (in) | 154 | Height (deployed; winch mast up) (mm) | 3,912 |

| Height (deployed; winch mast up) (ft) | 12.8 | Height (deployed; winch mast up) (m) | 3.91 |

| Base Unit Weight without DM sideshift (lbs) | 6,030 | Base Unit Weight without DM sideshift (kg) | 2,735 |

| Base Unit Weight with DM sideshift (lbs) | 6,250 | Base Unit Weight with DM sideshift (kg) | 2,835 |

| Ground Speed (mph) | 2.5 | Ground Speed (kph) | 4.0 |

| Estimated Track Surface Area (in2) | 1656 | Estimated Track Surface Area (cm2) | 10,681 |

| Estimated Ground Pressure (psi) | 3.8 | Estimated Ground Pressure (bar) | 0.26 |

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 15 | Extension (fore and aft) (mm) | 381 |

| Lateral (side to side if equipped) (± in) | 3 | Lateral (side to side if equipped) (± mm) | 76 |

| Oscillation (degrees from vertical) | NA | Oscillation (degrees from vertical) | NA |

| Drill Mast Dump (in) | 30 | Drill Mast Dump (mm) | 762 |

| Front outrigger travel (in) | NA | Front outrigger travel (mm) | NA |

| Rear stabilizer travel (in) | 27 | Rear outrigger travel (mm) | 686 |

| Rear stabilizer width (in) | 48 | Rear stabilizer width (mm) | 1,219 |

| Rear stabilizer lift (lbs) | 2000 | Rear stabilizer lift (kg) | 907 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 66 | Head Travel (mm) | 1,676 |

| Head Travel (ft) | 5.5 | Head Travel (m) | 1.68 |

| Head Crowd Force (lbs) | 36,000 | Head Crowd Force (kN) | 160 |

| Head Pull Force (lbs) | 48,000 | Head Pull Force (kN) | 214 |

| Head Feed Carriage | Comp. slides | Head Feed Carriage | Comp. slides |

| Head Feed Pressure Control (w.o.b) | Optional | Head Feed Pressure Control (w.o.b) | Optional |

| Prime Mover & Hydraulic Specs (Tier 4/Stage V) | Prime Mover & Hydraulic Specs (Tier 4) | ||

| Engine | Kubota V2403 Tier 4 Final | Engine | Kubota V2403 Tier 4 Final |

| Engine Rated Power (hp) | 65 | Engine Rated Power (kW) | 48 |

| Fuel Capacity (gal) | 14 | Fuel Capacity (L) | 53 |

| Pump type | Axial Piston | Pump type | Axial Piston |

| Max pressure (psi) | 3,400 | Max pressure (bar) | 234 |

| Max flow (gpm) | 24 | Max flow (L/min) | 91 |

| Additional Pump | NA | Additional Pump | NA |

| Prime Mover & Hydraulic Specs (LRC) | Prime Mover & Hydraulic Specs (LRC) | ||

| Engine | Kubota V1505 Tier 4i | Engine | Kubota V1505 Tier 4i |

| Engine Rated Power (hp) | 44 | Engine Rated Power (kW) | 33 |

| Fuel Capacity (gal) | 14 | Fuel Capacity (L) | 53 |

| Pump type | Axial Piston | Pump type | Axial Piston |

| Max pressure (psi) | 3,400 | Max pressure (bar) | 234 |

| Max flow (gpm) | 24 | Max flow (L/min) | 91 |

| Additional Pump | NA | Additional Pump | NA |

| Direct Push Hammer | Direct Push Hammer | ||

| GH63 | GH63 | ||

| Percussion rate (Hz) | 32 | Percussion rate (Hz) | 32 |

| Hammer Rotation Torque (ft-lb) | 560 | Hammer Rotation Torque (N-m) | 759 |

| Hammer Rotation Speed (rpm) | 200 | Hammer Rotation Speed (rpm) | 200 |

| Rotary Drive Options | Rotary Drive Options | ||

| 2-Speed Rotary Drive | GA2500 | 2-Speed Rotary Drive | GA2500 |

| Rotation Torque (Range 1) (ft-lb) | 2,500 | Rotation Torque (Range 1) (N-m) | 3,390 |

| Rotation Speed (Range 1) (rpm) | 70 | Rotation Speed (Range 2) (rpm) | 70 |

| Rotation Torque (Range 2) (ft-lb) | 1,250 | Rotation Torque (Range 1) (N-m) | 1,695 |

| Rotation Speed (Range 2) (rpm) | 150 | Rotation Speed (Range 2) (rpm) | 150 |

| Hex Adapter (in) | 1.625 | Hex Adapter (mm) | 41 |

| Primary Winch | Primary Winch | ||

| line pull (lbf) | 2500 | line pull (kN) | 11.12 |

| line speed (fpm) | 125 | line speed (m/min) | 38 |

| cable length (ft) | 100 | cable length (m) | 30 |

| Sub-component weight | Sub-component weight | ||

| Undercarriage Asm 11DT (lbm) | 1,050 | Undercarriage Asm 11DT (kg) | 476 |

| Undercarriage Asm 12DT (lbm) | 2,000 | Undercarriage Asm 12DT (kg) | 907 |

| 6712 Powertrain Asm Tier 4 (lbm) | 2,180 | 6712 Powertrain Asm Tier 4 (kg) | 989 |

| 6712 Powertrain Asm LRC (lbm) | 2,000 | 6712 Powertrain Asm (kg) | 907 |

| 6712 Drillmast with Sideshift (lbm) | 2,000 | 6712 Drillmast with Sideshift (kg) | 907 |

| 6712 Drillmast quick-attach (lbm) | 1,780 | 6712 Drillmast quick-attach (kg) | 807 |

| CPT Mast Asm (lbm) | 2,500 | CPT Mast Asm (kg) | 1,134 |

| Auger head attachement 2 speed (lbm) | 348 | Auger head attachement 2 speed (kg) | 158 |

| Hyd Winch/Mast Asm PM6712DT (lbm) | 302 | Hyd Winch/Mast Asm PM6712DT (kg) | 137 |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 52 | Width (mm) | 1,321 |

| Length (transport) (in) | 116 | Length (transport) (mm) | 2,946 |

| Length (deployed, lateral fully extended) (in) | 167 | Length (deployed, lateral fully retracted) (mm) | 4,242 |

| Height (normal transport) (in) | 83 | Height (normal transport) (mm) | 2,108 |

| Height (deployed; Head up) (in) | 154 | Height (deployed; winch mast up) (mm) | 3,912 |

| Height (deployed; winch mast up) (ft) | 12.8 | Height (deployed; winch mast up) (m) | 3.91 |

| Base Unit Weight without DM sideshift (lbs) | 6,030 | Base Unit Weight without DM sideshift (kg) | 2,735 |

| Base Unit Weight with DM sideshift (lbs) | 6,250 | Base Unit Weight with DM sideshift (kg) | 2,835 |

| Ground Speed (mph) | 2.5 | Ground Speed (kph) | 4.0 |

| Estimated Track Surface Area (in2) | 1656 | Estimated Track Surface Area (cm2) | 10,681 |

| Estimated Ground Pressure (psi) | 3.8 | Estimated Ground Pressure (bar) | 0.26 |

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 15 | Extension (fore and aft) (mm) | 381 |

| Lateral (side to side if equipped) (± in) | 3 | Lateral (side to side if equipped) (± mm) | 76 |

| Oscillation (degrees from vertical) | NA | Oscillation (degrees from vertical) | NA |

| Drill Mast Dump (in) | 30 | Drill Mast Dump (mm) | 762 |

| Front outrigger travel (in) | NA | Front outrigger travel (mm) | NA |

| Rear stabilizer travel (in) | 27 | Rear outrigger travel (mm) | 686 |

| Rear stabilizer width (in) | 48 | Rear stabilizer width (mm) | 1,219 |

| Rear stabilizer lift (lbs) | 2000 | Rear stabilizer lift (kg) | 907 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 66 | Head Travel (mm) | 1,676 |

| Head Travel (ft) | 5.5 | Head Travel (m) | 1.68 |

| Head Crowd Force (lbs) | 36,000 | Head Crowd Force (kN) | 160 |

| Head Pull Force (lbs) | 48,000 | Head Pull Force (kN) | 214 |

| Head Feed Carriage | Comp. slides | Head Feed Carriage | Comp. slides |

| Head Feed Pressure Control (w.o.b) | Optional | Head Feed Pressure Control (w.o.b) | Optional |

| Prime Mover & Hydraulic Specs (Tier 4/Stage V) | Prime Mover & Hydraulic Specs (Tier 4) | ||

| Engine | Kubota V2403 Tier 4 Final | Engine | Kubota V2403 Tier 4 Final |

| Engine Rated Power (hp) | 65 | Engine Rated Power (kW) | 48 |

| Fuel Capacity (gal) | 14 | Fuel Capacity (L) | 53 |

| Pump type | Axial Piston | Pump type | Axial Piston |

| Max pressure (psi) | 3,400 | Max pressure (bar) | 234 |

| Max flow (gpm) | 24 | Max flow (L/min) | 91 |

| Additional Pump | NA | Additional Pump | NA |

| Prime Mover & Hydraulic Specs (LRC) | Prime Mover & Hydraulic Specs (LRC) | ||

| Engine | Kubota V1505 Tier 4i | Engine | Kubota V1505 Tier 4i |

| Engine Rated Power (hp) | 44 | Engine Rated Power (kW) | 33 |

| Fuel Capacity (gal) | 14 | Fuel Capacity (L) | 53 |

| Pump type | Axial Piston | Pump type | Axial Piston |

| Max pressure (psi) | 3,400 | Max pressure (bar) | 234 |

| Max flow (gpm) | 24 | Max flow (L/min) | 91 |

| Additional Pump | NA | Additional Pump | NA |

| Direct Push Hammer | Direct Push Hammer | ||

| GH63 | GH63 | ||

| Percussion rate (Hz) | 32 | Percussion rate (Hz) | 32 |

| Hammer Rotation Torque (ft-lb) | 560 | Hammer Rotation Torque (N-m) | 759 |

| Hammer Rotation Speed (rpm) | 200 | Hammer Rotation Speed (rpm) | 200 |

| Rotary Drive Options | Rotary Drive Options | ||

| 2-Speed Rotary Drive | GA2500 | 2-Speed Rotary Drive | GA2500 |

| Rotation Torque (Range 1) (ft-lb) | 2,500 | Rotation Torque (Range 1) (N-m) | 3,390 |

| Rotation Speed (Range 1) (rpm) | 70 | Rotation Speed (Range 2) (rpm) | 70 |

| Rotation Torque (Range 2) (ft-lb) | 1,250 | Rotation Torque (Range 1) (N-m) | 1,695 |

| Rotation Speed (Range 2) (rpm) | 150 | Rotation Speed (Range 2) (rpm) | 150 |

| Hex Adapter (in) | 1.625 | Hex Adapter (mm) | 41 |

| Primary Winch | Primary Winch | ||

| line pull (lbf) | 2500 | line pull (kN) | 11.12 |

| line speed (fpm) | 125 | line speed (m/min) | 38 |

| cable length (ft) | 100 | cable length (m) | 30 |

| Sub-component weight | Sub-component weight | ||

| Undercarriage Asm 11DT (lbm) | 1,050 | Undercarriage Asm 11DT (kg) | 476 |

| Undercarriage Asm 12DT (lbm) | 2,000 | Undercarriage Asm 12DT (kg) | 907 |

| 6712 Powertrain Asm Tier 4 (lbm) | 2,180 | 6712 Powertrain Asm Tier 4 (kg) | 989 |

| 6712 Powertrain Asm LRC (lbm) | 2,000 | 6712 Powertrain Asm (kg) | 907 |

| 6712 Drillmast with Sideshift (lbm) | 2,000 | 6712 Drillmast with Sideshift (kg) | 907 |

| 6712 Drillmast quick-attach (lbm) | 1,780 | 6712 Drillmast quick-attach (kg) | 807 |

| CPT Mast Asm (lbm) | 2,500 | CPT Mast Asm (kg) | 1,134 |

| Auger head attachement 2 speed (lbm) | 348 | Auger head attachement 2 speed (kg) | 158 |

| Hyd Winch/Mast Asm PM6712DT (lbm) | 302 | Hyd Winch/Mast Asm PM6712DT (kg) | 137 |

Operator Side - Unfolded

Front - Low-Clearance Cylinder Option

Operator Side - Folded

Front - Folded

Resources

Click on a section below to view information.

6712DT delivers the power and agility needed for injection point projects.

ID: 14614 | Date:

6712DT's size and power is perfect for not only soil sampling and landfill gas collection but also monitoring well installation.

ID: 14363 | Date:

Pairing the 6712DT with the 20CPT Press makes a system that is faster, safer, and more efficient.

ID: 14362 | Date:

Direct Image® Tooling provides high-quality data in the unforgiving geology of Alaska.

ID: 14360 | Date:

Primarily roaming within a 100-mile radius of Philadelphia, TRISTATE ENVIRONMENTAL MANAGEMENT SERVICES performs a broad range of environmental field services in New Jersey and Southeast Pennsylvania. Project Manager Ted Sobieski credits their “jack-of-all

ID: 13417 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.