6011DT Drill Rig

Video: Geoprobe® 6011DT Overview

Small Drill Rig with Big Direct Push Drill Rig Power

Drillers seeking a small footprint, but big direct push drill rig power, choose the 6011DT to efficiently track into tight spots or through tough terrain. The rig features a proven GH63 percussion hammer while still being sized to slip into small spaces. Easily mobilize the lightweight rig to your direct push jobs with confidence to complete sampling.

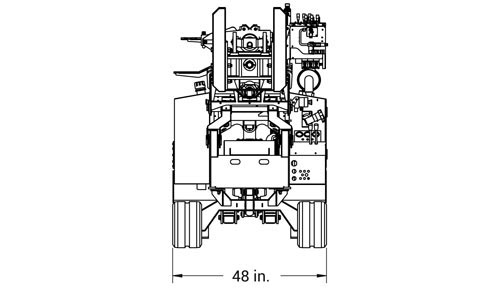

- 48-inches wide, 4,800 lb direct push drill rig only platform

- GH63 percussion hammer, uses 5-foot tooling

- 44 horsepower engine

- Optional low clearance cylinder for indoor spaces

- Rear stabilizer blade works with Geoprobe® drop racks

- Load-sense hydraulics reduce fuel consumption

- Affordable price point

- Suited for Direct Image® logging tools and CPT

- International configuration with engine for lesser regulated countries

Features & Options

- 48-inches wide, 4,800 lb direct push only platform

- GH63 percussion hammer, uses 5-foot tooling

- 44 horsepower engine

- Optional low clearance cylinder for indoor spaces

- Rear stabilizer blade works with Geoprobe® drop racks

- Load-sense hydraulics reduce fuel consumption

- Affordable price point

- Suited for Direct Image® logging tools and CPT

- International configuration with engine for lesser regulated countries

- Tier 4/Stage V engine

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your portable drill rig is constructed consistently and tested thoroughly to ensure easier service support.

Features & Options

- 48-inches wide, 4,800 lb direct push only platform

- GH63 percussion hammer, uses 5-foot tooling

- 44 horsepower engine

- Optional low clearance cylinder for indoor spaces

- Rear stabilizer blade works with Geoprobe® drop racks

- Load-sense hydraulics reduce fuel consumption

- Affordable price point

- Suited for Direct Image® logging tools and CPT

- International configuration with engine for lesser regulated countries

- Tier 4/Stage V engine

With drill rig service shops in North Carolina, Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your portable drill rig is constructed consistently and tested thoroughly to ensure easier service support.

Tooling & Accessories

Video: DT22 Soil Sampling System Overview

The Geoprobe® DT22 Soil Sampling System is a direct push system for collecting continuous core samples of unconsolidated materials from within a sealed casing of Geoprobe® 2.25- inch outside diameter probe rods. Samples are collected and retrieved within a liner that is threaded onto the leading end of a string of Geoprobe® 1.25-inch OD light-weight center rods and are inserted to the bottom of the outer casing.

Video: SP22-ISP Groundwater Sampler

The Screen Point 22 (SP22) Groundwater Sampler from Geoprobe Systems® was designed to keep the screen away from all percussive energy while the sampler is lowered downhole, thus extending the life of the screen.The SP22 can be used alone as a groundwater grab sampler or groundwater profiling tool, or with the DT22 Soil Sampling System. The screens can be deployed using either 1.25-inch Lightweight Center Rods or PVC riser.Designed for tough probing conditions, the screen head on the fully retrievable sampler adapts to either a stainless steel or PVC screen.

Video: MC5 Soil Sampling - Step by Step

Our MC5 Soil Sampling System is a single tube, discrete or continuous system with unmatched durability.MC5 Light Weight Center Rod Soil Sampling System. The MC5 1.25-inch Center Rod System was designed for the absolute worst of the worst direct push probing conditions. “These are conditions that we normally do not recommend probing in,” according to Mike Carlin, Project Engineer, “so we developed the toughest soil sampling system in the direct push industry ... it’s a brute!”Macro-Core® is a registered trademark of Kejr, Inc., Salina, KS.

Videos

ID: 12726

ID: 5732

Specs

Specifications are subject to change without notice.

| Standard | Metric | ||

| 6011DT | 6011DT | ||

| Overall Dimensions | Overall Dimensions | ||

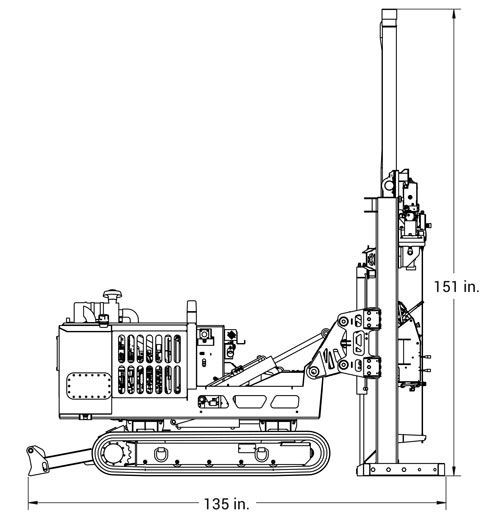

| Width (in) | 48 | Width (mm) | 1219 |

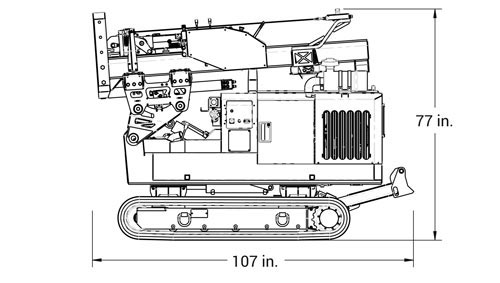

| Length (transport) (in) | 106 | Length (transport) (mm) | 2692 |

| Length (deployed, lateral fully extended) (in) | 151.5 | Length (deployed, lateral fully retracted) (mm) | 3848 |

| Height (normal transport) (in) | 77 | Height (normal transport) (mm) | 1956 |

| Height (deployed; head full up) (in) | 151 | Height (deployed; head full up) (mm) | 3835 |

| Height (deployed; head full up) (ft) | 12.6 | Height (deployed; head full up) (m) | 3.84 |

| Base Unit Weight (lbs) | 4,800 | Base Unit Weight (kg) | 2,177 |

| Ground Speed (mph) | 3 | Ground Speed (kph) | 4.8 |

| Estimated Track Surface Area (in2) | 1134 | Estimated Track Surface Area (cm2) | 7,314 |

| Estimated Ground Pressure (psi) | 4.2 | Estimated Ground Pressure (bar) | 0.29 |

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 15 | Extension (fore and aft) (mm) | 381 |

| Lateral (side to side) (in) | 6 | Lateral (side to side) (± degrees) | 6 |

| Drill Mast Dump (in) | 30 | Drill Mast Dump (mm) | 762 |

| Rear stabilizer travel (in) | 24 | Rear outrigger travel (mm) | 610 |

| Rear stabilizer width (in) | 48 | Rear stabilizer width (mm) | 1219 |

| Rear stabilizer lift (lbs) | 1250 | Rear stabilizer lift (kg) | 567 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 66 | Head Travel (mm) | 1676 |

| Head Travel (ft) | 5.5 | Head Travel (m) | 1.68 |

| Head Crowd Force (lbs) (at cylinder) | 32,000 | Head Crowd Force (kN) (at cylinder) | 142 |

| Head Pull Force (lbs) (at cylinder) | 43,000 | Head Pull Force (kN) (at cylinder) | 191 |

| Head Feed Carriage | Comp. slides | Head Feed Carriage | Comp. slides |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | Kubota V1505 (LRC) | Engine | Kubota V1505 (LRC) |

| Engine Rated Power (hp) | 44 | Engine Rated Power (kW) | 33 |

| Fuel Capacity (gal) | 18 | Fuel Capacity (L) | 68 |

| Pump type | Axial Piston - Load Sense | Pump type | Axial Piston - Load Sense |

| Max pressure (psi) | 3,400 | Max pressure (bar) | 234 |

| Max flow (gpm) | 24 | Max flow (L/min) | 91 |

| Direct Push Hammer | Direct Push Hammer | ||

| GH63 | GH63 | ||

| Percussion rate (Hz) | 32 | Percussion rate (Hz) | 32 |

| Hammer Rotation Torque (ft-lb) | 560 | Hammer Rotation Torque (N-m) | 759 |

| Hammer Rotation Speed (rpm) | 200 | Hammer Rotation Speed (rpm) | 200 |

| Options | Options | ||

| Side Rod Rack -- DP | Side Rod Rack -- DP | ||

| Side Rod Rack -- DI | Side Rod Rack -- DI | ||

| CPT Rate control | CPT Rate control | ||

| Interlocked Rotation Guard | Interlocked Rotation Guard | ||

| Drop Rack | Drop Rack |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| Standard | Metric | ||

| 6011DT | 6011DT | ||

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 48 | Width (mm) | 1219 |

| Length (transport) (in) | 106 | Length (transport) (mm) | 2692 |

| Length (deployed, lateral fully extended) (in) | 151.5 | Length (deployed, lateral fully retracted) (mm) | 3848 |

| Height (normal transport) (in) | 77 | Height (normal transport) (mm) | 1956 |

| Height (deployed; head full up) (in) | 151 | Height (deployed; head full up) (mm) | 3835 |

| Height (deployed; head full up) (ft) | 12.6 | Height (deployed; head full up) (m) | 3.84 |

| Base Unit Weight (lbs) | 4,800 | Base Unit Weight (kg) | 2,177 |

| Ground Speed (mph) | 3 | Ground Speed (kph) | 4.8 |

| Estimated Track Surface Area (in2) | 1134 | Estimated Track Surface Area (cm2) | 7,314 |

| Estimated Ground Pressure (psi) | 4.2 | Estimated Ground Pressure (bar) | 0.29 |

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 15 | Extension (fore and aft) (mm) | 381 |

| Lateral (side to side) (in) | 6 | Lateral (side to side) (± degrees) | 6 |

| Drill Mast Dump (in) | 30 | Drill Mast Dump (mm) | 762 |

| Rear stabilizer travel (in) | 24 | Rear outrigger travel (mm) | 610 |

| Rear stabilizer width (in) | 48 | Rear stabilizer width (mm) | 1219 |

| Rear stabilizer lift (lbs) | 1250 | Rear stabilizer lift (kg) | 567 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 66 | Head Travel (mm) | 1676 |

| Head Travel (ft) | 5.5 | Head Travel (m) | 1.68 |

| Head Crowd Force (lbs) (at cylinder) | 32,000 | Head Crowd Force (kN) (at cylinder) | 142 |

| Head Pull Force (lbs) (at cylinder) | 43,000 | Head Pull Force (kN) (at cylinder) | 191 |

| Head Feed Carriage | Comp. slides | Head Feed Carriage | Comp. slides |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | Kubota V1505 (LRC) | Engine | Kubota V1505 (LRC) |

| Engine Rated Power (hp) | 44 | Engine Rated Power (kW) | 33 |

| Fuel Capacity (gal) | 18 | Fuel Capacity (L) | 68 |

| Pump type | Axial Piston - Load Sense | Pump type | Axial Piston - Load Sense |

| Max pressure (psi) | 3,400 | Max pressure (bar) | 234 |

| Max flow (gpm) | 24 | Max flow (L/min) | 91 |

| Direct Push Hammer | Direct Push Hammer | ||

| GH63 | GH63 | ||

| Percussion rate (Hz) | 32 | Percussion rate (Hz) | 32 |

| Hammer Rotation Torque (ft-lb) | 560 | Hammer Rotation Torque (N-m) | 759 |

| Hammer Rotation Speed (rpm) | 200 | Hammer Rotation Speed (rpm) | 200 |

| Options | Options | ||

| Side Rod Rack -- DP | Side Rod Rack -- DP | ||

| Side Rod Rack -- DI | Side Rod Rack -- DI | ||

| CPT Rate control | CPT Rate control | ||

| Interlocked Rotation Guard | Interlocked Rotation Guard | ||

| Drop Rack | Drop Rack |

Helper Side - Unfolded

Operator Side - Folded

Front - Folded

Resources

Click on a section below to view information.

6011DT’s compact design and GH63 hammer let you reach depth in tight-access sites.

ID: 14615 | Date:

The power of the GH63 hammer on the 6011DT was put to the test in an indoor, low-clearance site.

ID: 14364 | Date:

The small footprint of the 6011DT slides into tight indoor spaces for site investigations.

ID: 14026 | Date:

Focused on vapor intrusion, H&P MOBILE GEOCHEMISTRY is one of few companies in their region of California to offer a one-stop-shop for completing vapor probe installation, soil gas sampling, and analyses.

ID: 13418 | Date:

Coming in at 48-inches wide and sporting a GH63 percussion hammer, the NEW 6011DT debuted during Open House delivered a powerful punch to the direct push drilling industry, convincing customers it can solve their predicaments.

ID: 5930 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.