Groundwater Monitoring Gets a Direct Push!

So, why is groundwater monitoring important you ask? And what does 'direct push' have to do with it? And for that matter, what is 'direct push'?

This article originally appeared in the September 2002 issue of Environmental Protection, Vol. 13, No. 8, p. 49.

Written by Wesley McCall, Geologist KS2

Geoprobe Systems®

Well (no pun intended), let's deal with these questions one at a time, and then put them together and see where that leads us. One obvious reason groundwater is so important is that almost 50 percent of Americans rely on water derived from their residential or public supply well for their everyday needs of drinking, cooking and cleaning.

In addition, a tremendous amount of groundwater is used for industrial processes, production, and cooling. So, if the quality of the water is degraded, or contaminated with hazardous chemicals every other American on the street is potentially at risk. That is no trivial concern. Not only is this a concern in urban and suburban areas, where industrial contamination is prevalent, but it is also a concern in our rural farming communities. The rural communities are where chemical fertilizers, herbicides and pesticides often contaminate the only available drinking water supply. Two movies produced by Hollywood over the last few years [Erin Brockovitch starring Julia Roberts (Universal Studios) and A Civil Action starring John Travolta (Touchstone/Paramount Pictures)] have helped to raise the level of awareness regarding the threat of groundwater contamination to the average family and neighborhood. Both films are based on true stories. In Erin Brockovitch improper disposal of cooling tower water containing hexavalent chromium contaminated residential wells which resulted in dozens of residents being stricken with serious malignancies, some resulting in loss of life. In the film A Civil Action improper dumping of Trichloroethene (TCE) and other volatile organic solvents led to contamination of municipal drinking water wells and resulted in increased incidence of malignancies and leukemia, and again, loss of life, eight of them children. Do you want your children to drink that water? It gets personal when placed in these terms.

What Is Direct Push (DP)?

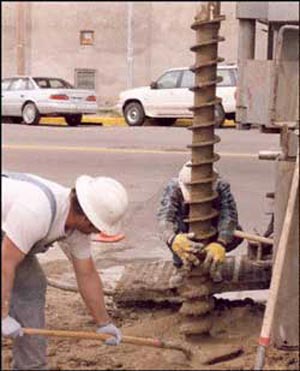

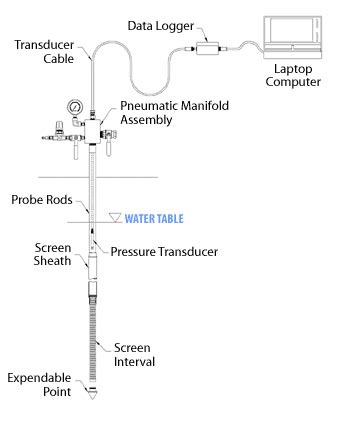

Now we know why groundwater monitoring is important; it enables us to detect contaminated groundwater that may be a threat to the health and welfare of our loved ones, friends, and neighbors. So what is 'direct push' and what is its significance here? Direct push (DP) is an alternative method (Figure 1) to conventional drilling techniques for sampling soil and groundwater, and installing monitoring wells in unconsolidated materials such as clay, silt, sand, and gravel. Many sites where groundwater is contaminated are located over aquifers of unconsolidated sands and gravels. DP methods do not use rotary augering to advance tools or install wells as conventional drilling methods do. DP methods use percussion hammers and static vehicle weight combined with hydraulic cylinders to advance tools to depth. The DP methods do not generate a large volume of potentially contaminated drill cuttings as conventional drilling methods do (Figures 2 & 3). This means that the field investigators and local residents are less likely to be exposed to contaminated media. The waste cuttings generated by conventional drilling usually have to be shoveled into drums, the drums are sampled for analysis, and if contaminated, the drummed cuttings must be shipped off for proper disposal. Costs for handling and disposal of these wastes often consume 25 percent to 50 percent of the investigation budget. Since these waste cuttings are not generated by DP methods, these costs are not incurred. Studies by the EPA (1998) and state agencies (Florida DEP, 1997) found that when DP methods were used the funds usually allocated for handling and disposal of these wastes may be used for better characterization of the site, or simply realized as savings and cost reduction. This is only one of the advantages of DP investigation methods.

Direct push methods for soil and groundwater sampling have been in use for ten years or more. These methods are widely accepted in all 50 states for RCRA, CERCLA, UST, (Resource Conservation and Recovery Act, Comprehensive Environmental Response Compensation and Liability Act [Superfund], Underground Storage Tank) and Brownfields site assessments and investigations (Applegate et al. 1997; Thorton et al. 1997; EPA 1997,1998). The American Society of Testing and Materials (ASTM) D18 Subcommittee on Direct Push Sampling (D18.21.01) has developed and published a Standard Guide for both soil sampling (D 6282) and groundwater sampling (D 6001) using direct push methods. In the last several years many state agencies have begun to accept and integrate these direct push soil and groundwater sampling methods into their regulatory frame work. More recently the equipment and procedures to install monitoring wells with DP methods have been developed. Are these new DP procedures for monitoring well installation being accepted in the industry? And what is the difference between a monitoring well and a groundwater sampler? Let's address the latter question first and then get back to the acceptance of the technology.

Groundwater Samplers vs. Monitoring Wells

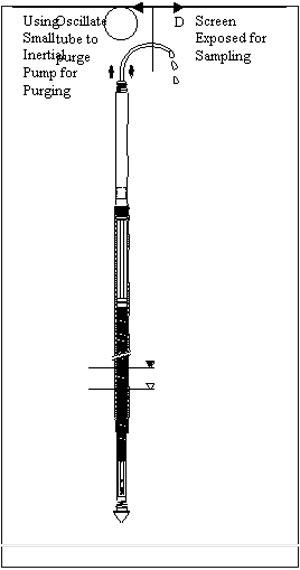

One thing that is confusing for many people when they are first introduced to DP sampling methods is the distinction between a temporary groundwater sampling tool and a monitoring well installed by DP methods. The DP installed temporary groundwater sampling tools (Figure 4) have been used for over ten years to conduct groundwater assessments during environmental investigations. These temporary groundwater samplers provide an efficient and cost effective means to define the vertical and lateral extent of groundwater contamination without the expense of installing permanent monitoring wells. These devices are advanced to depth, a groundwater sample is collected, and the sampler is retrieved and decontaminated. These tools are designed so that the installation, sampling, and retrieval process often requires less than an hour, and once decontaminated, the device may be used again and again. This DP capability significantly lowers the cost of a groundwater investigation, often by more than 50 percent when compared to conventional drilling and installation of permanent monitoring wells previously used for these investigations (EPA 1998).

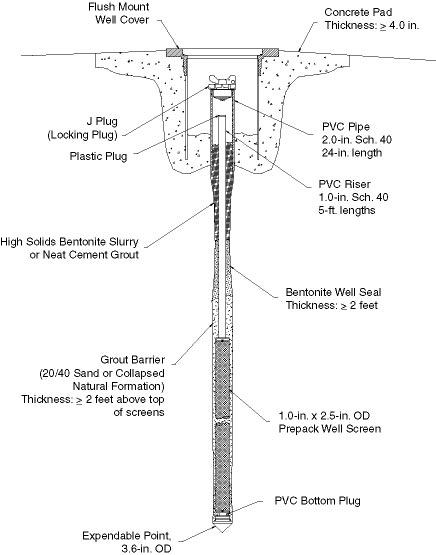

But, you ask, what about monitoring contaminated groundwater over a long period of time? You need to determine if the contamination is persistent, increasing in concentration, spreading to potential receptors (you or me?), or decreasing in concentration due to natural attenuation or an engineered remedial system. Now you need monitoring wells that can remain in place and provide representative samples on a regular basis, often for ten or more years. Do you have to resort to the less efficient, more hazardous and costly conventional drilling methods to install these monitoring wells? Do you need a two-inch or four-inch diameter well to collect two 40-milliliter vials for sample analysis? No. Direct push methods are available for installing small diameter (0.5 to 1.5-inch ID) high integrity monitoring wells in unconsolidated formations (Figure 5). Depending on the transmissivity of the formation screened the DP wells can yield more than a liter of water per minute for sampling. These small diameter wells are also ideal for use when following the EPA's stringent "Low-Flow" sampling protocol (EPA 1996) to obtain high integrity samples. The new ASTM Standard Guide (D 6724) outlines several options to install monitoring wells for environmental water quality sampling. More detailed information is provided in the ASTM Standard Practice (D 6725) for installing monitoring wells with prepacked screens (Figure 6). The use of prepacked screens with the smaller diameter DP tools makes well installation easier and more rapid. The prepacked screens also assure the integrity and placement of the filter media during well construction providing confidence that low turbidity, representative samples will be obtained. Furthermore, the equipment and methods for tremie grouting the small annulus of the DP tooling has been developed so that high integrity well seals and annular grout prevent movement of contaminants down hole and alleviate concerns of potential cross contamination.

Technology Verification and Acceptance

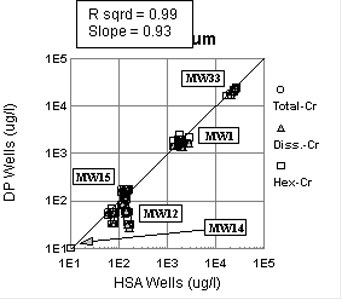

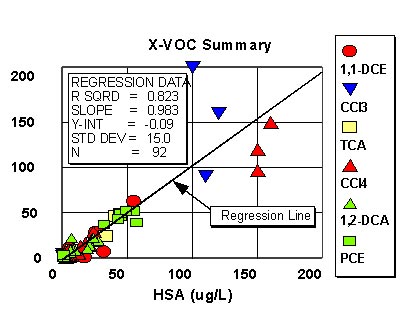

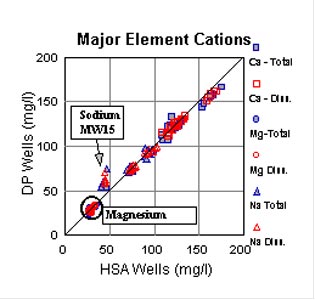

Many regulatory agencies, consultants, and facility owners are reluctant to use a new technology or method. They are concerned about a new technology's ability to provide representative samples, regulatory acceptance, and legal defensibility (the inevitable). Some initial field studies conducted to determine if DP installed wells provide representative samples comparable to those recovered from conventionally installed monitoring wells. Two of these early studies (McCall et al. 1997, McCall 2000) report that the DP prepacked screen monitoring wells provide equivalent samples for several analytes. The analytes studied in the comparisons included chlorinated volatile organic compounds (Figure 7a), hexavalent chromium (Figure 7b), and major element cations (Figure 7c). These studies found no statistically significant difference between the paired DP and conventional wells for the analytes investigated. Additional studies comparing DP and conventionally installed monitoring wells are currently being conducted by the Department of Defense. The DOD studies are being conducted at Port Hueneme, California; Tyndall Air Force Base, Florida; the Cold Regions Research and Engineering Laboratory (CRREL) in New Hampshire; and at least two other facilities. The study being conducted at Port Hueneme has focused on the gasoline additive, methyl tertiary butyl ether (MTBE). The preliminary report from this study (Kram et al. 2000) found no statistically significant difference between the performance of the DP installed and conventionally installed monitoring wells.

So, what about acceptance of the new DP methods for installing monitoring wells? Are state regulatory agencies and the U.S. EPA embracing these new methods? Simply stated, yes. One recent example is the Oregon Water Resources Department. See their Administrative Rules Chapter 690, Division 240, Well Construction Standards, for an example of updated regulations that embrace this new technology. The new, and soon to be published ASTM Standard Guide (D 6724) and Standard Practice (D 6725) for installation of direct push monitoring wells should facilitate broader acceptance of the DP well installation technology for groundwater monitoring. Because of the recently enacted Public Law (No. 104-113) federal agencies (such as the EPA) accept and adopt technical standards developed by voluntary consensus standards organizations such as ASTM. Information on this topic is available from the Office of Management and Budget in Circular No. A-119 entitled "Federal Participation in the Development and Use of Voluntary Consensus Standards".

Hydraulic Conductivity Too!

Monitoring wells also are used to obtain another essential piece of information about the aquifer or formation under investigation. The monitoring wells are used to determine the formation hydraulic conductivity by conducting pump tests or slug tests. Hydraulic conductivity (K) measurements allow calculation of the rate that groundwater (and so contaminants) can flow through the formation. If the groundwater and contaminants move quickly enough they may reach a water supply well before they are degraded by natural attenuation and so pose a significant health risk to the local family or community.

Can direct push installed wells and groundwater samplers be used to determine the formation hydraulic conductivity? Recently published research (Butler et al. 2002, Butler 2002, McCall et al. 2002) has found that the small diameter DP installed devices can provide an accurate determination of the formation hydraulic conductivity when appropriate methods are used (Figure 8). Data on K is used in risk based modeling (RBCA) and to determine if Monitored Natural Attenuation (MNA) is an acceptable remedial alternative. Additionally, data on K is essential so that groundwater remedial systems can be correctly designed.

Summary

Now you know that "direct push" is an alternative method to conventional drilling for collection of soil and groundwater samples and the installation of monitoring wells in unconsolidated materials such as clay, silt, sand, and gravel. Also, direct push is time and cost effective and minimizes the generation of hazardous wastes during environmental investigations. To summarize, why would you want to install smaller diameter monitoring wells using direct push methods?

· Save time and money

· Obtain representative samples

· Minimize waste generation and exposure hazards

· Obtain data required by regulation to meet monitoring, investigation, remediation, and closure requirements

· Obtain information on formation hydraulic conductivity needed for RBCA/MNA and remedial action design.

And don't forget to follow the recently published ASTM Guide (D 6724) and Practice (D 6725) for direct push well installation to assure the quality of well construction and groundwater sample integrity. Let's monitor our valuable groundwater resources and protect our families and neighbors more effectively using smarter methods.

References

Applegate, Joseph L., and Douglas M. Fitton, 1997. Rapid Site Assessment Applied to the Florida Department of Environmental Protections's Drycleaning Solvent Cleanup Program. In Superfund XVIII Conference Proceedings Volume II. PP 695-703. E.J. Krause and Assoc.

ASTM 1999b. D 6282 Standard Guide for Direct Push Soil Sampling for Environmental Site Characterizations. In Annual Book of ASTM Standards Vol. 04.09 Soil and Rock (II). ASTM West Conshohocken, PA.

ASTM 1999c. D6001 Standard Guide for Direct-Push Water Sampling for Geoenvironmental Investigations. In Annual Book of ASTM Standards Vol. 04.09 Soil and Rock (II). ASTM West Conshohocken, PA.

ASTM D 6724. Standard Guide for Selection and Installation of Direct Push Ground Water Monitoring Wells. ASTM West Conshohocken, PA. In Press.

ASTM D 6725. Standard Practice for Direct Push Installation of Prepacked Screen Monitoring Wells in Unconsolidated Aquifers. ASTM West Conshohocken, PA. In Press.

Butler, James J. Jr., John M. Healey, G. Wesley McCall, Elizabeth J. Garnett and Steven P. Loheide II, 2002. Hydraulic Tests with Direct-Push Equipment. Ground Water Vol. 40, No. 1(??).

Butler, James J. Jr., 2002. Technical Note: A Simple Correction for Slug Tests in Small-Diameter Wells. Ground Water, Vol. 40, No. 3.

EPA 1991. Handbook of Suggested Practices for the Design and Installation of Ground-Water Monitoring Wells. Office of Research and Development, Washington, D.C. EPA/600/4-89/034. March

EPA 1996. Ground Water Issue: Low-Flow (Minimal Drawdown) Ground-Water Sampling Procedures. EPA/540/S-95/504. April.

EPA 1997. Expedited Site Assessment Tools for Underground Storage Tank Sites: A Guide for Regulators. Solid Waste and Emergency Response 5403G. EPA 510-B-97-001. March.

EPA 1998. Seminars - Monitored Natural Attenuation for Ground Water. EPA/625/K-98/001. Office of Research and Development, Washington, D.C. September.

Kram, Mark; Dale Lorenza, Joel Michaelson and Ernest Lory, 2000. Performance Comparison: Direct-Push Wells Versus Drilled Wells. NFESC Technical Report TR-2120-ENV. Naval Facilities Engineering Command, Washington, D.C. October.

McCall, Wesley, Susan Stover, Curt Enos and Greg Fuhrman, 1997. Field Comparison of Direct Push Prepacked Screen Wells to Paired HSA 2" Wells. In: Superfund XVIII Conference Proceedings Vol. 2. E.J. Krause & Assoc. December.

McCall, Wesley, 2000b. Innovative Direct Push Ground Water Monitoring Compared to Conventional Methods. In: Vol. 2, Risk Regulatory and Monitoring Considerations of the Second International Conference on Remediation of Chlorinated and Recalcitrant Compounds. Battelle Press. Columbus, OH. pp 71 -78.

McCall, Wesley, James J. Butler, Jr., John Healey, Alyssa Lanier, Stephen Sellwood and Elizabeth Garnett, 2002. A Dual-Tube Direct-Push Method for Vertical Profiling of Hydraulic Conductivity in Unconsolidated Formations. Environmental & Engineering Geosciences, Vol. 8, No. 2. Assoc. of Engineering Geologists.

Thornton, Daniel, Stacey Ita and Kenyon Larsen, 1997. Broader Use of Innovative Ground Water Access Technologies. In Superfund XVIII Conference Proceedings Volume II. PP 639-646. E.J. Krause and Assoc.

Contact Us

1835 Wall Street

Salina, Kansas 67401

Phone: (785) 825-1842

Related Videos

ID: 1988