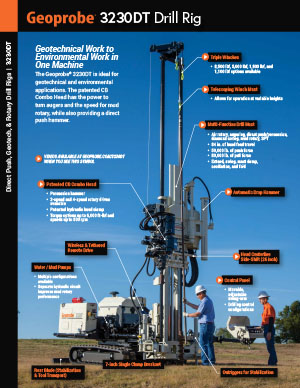

3230DT Drill Rig

Video: Geoprobe® 3230DT Overview

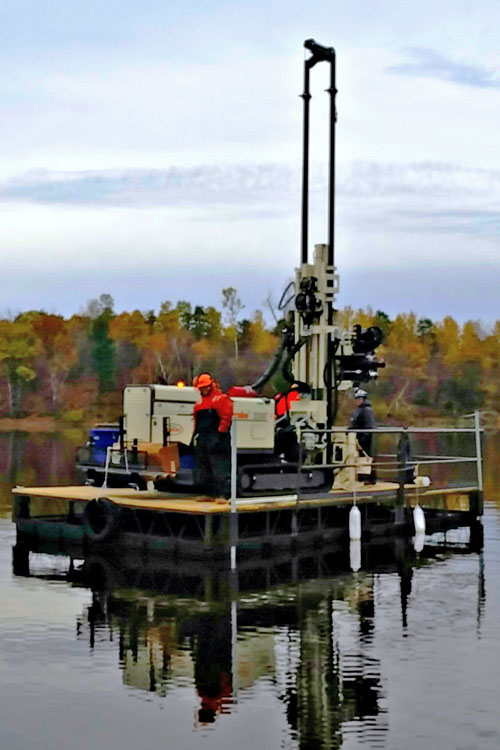

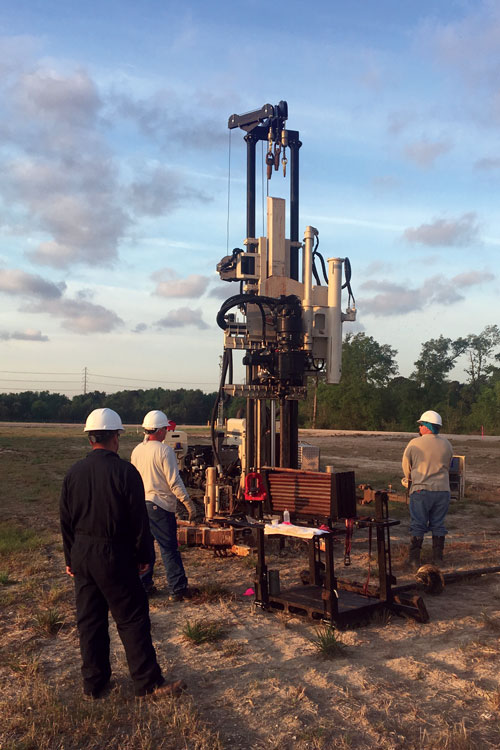

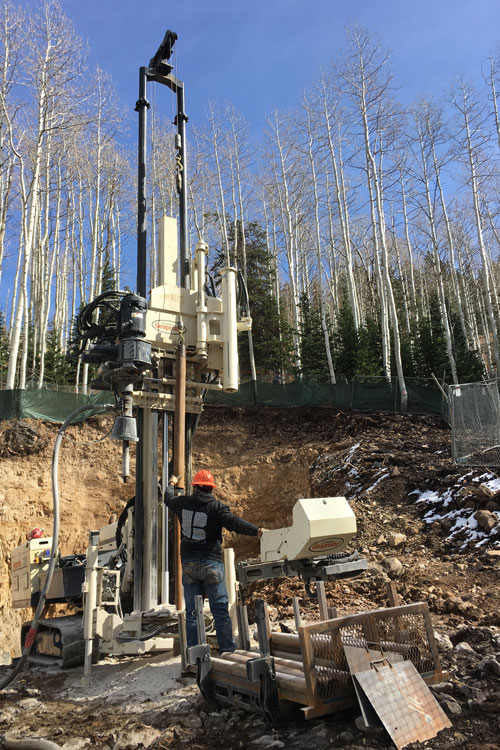

Expand Your Scope of Work

Drillers seeking to maximize footage by performing rotary drilling and direct push sampling with a single drill rig appreciate the versatility of the 3230DT. Known for providing precision head feed control and straight and rigid top-head driven design, the latest 3230DT drill rig adds horsepower and fuel-saving hydraulic features. Additional advantages of the drill rig include:

- Increased productivity with ability to quickly switch from coring rock to pushing CPT for example

- Expanded applications through combination of geotechnical augering, high-speed rotary, and advanced direct push capabilities

- Enhanced safety created by double breakout and adjustable swing-arm control panel

Features such as feed rate and weight on bit controls allow new drillers to see what a 30-year-experienced driller knows, providing them confidence. Companies notice training new drillers and making them productive as they’re coming up the curve is easier on a Geoprobe® drill rig thanks to:

- Digital readouts providing instant feedback

- Safety enhancing features

- Easy operation, building confidence

- Availability of training options

Features & Options

Video: Geoprobe® 3230DT Overview

Owners praise their Geoprobe® 3230DT drill rig for their ability to compete for geotechnical projects while expanding their environmental work. With numerous features and configurations for success, crews rely on the 3230DT combination drill rig for its power and precision.

- TASKS: possess power for hollow stem augers along with finesse for high-speed wireline tools with the torque and rotary range of the patented CB combo head. Experience versatility with ease by adding a powerful GH70 hammer, switching between tasks quickly. Need to auger to bedrock and then do a confirmation core? You’re ready with ONE MACHINE.

- TRANSITIONS: work the inside diameter of the rod without moving the drill mast thanks to head travel along center. Conveniently transition from driving casing via direct push to wet rotary drilling ... in less than five minutes. Hold or pull rods, casings, or augers while maintaining an open tool string using the patented hydraulic head clamp, which easily manages the 80,000 lb. of pullback.

- TAILORED: customize site setup by positioning the telescoping winch mast as well as the height and angle of the adjustable swing-arm control panel, steering clear of spinning tool strings or positioning comfortably close to align rods. Precisely dial in speeds, feeds, and pumps with the intuitive electronic controls. Equip the rig for your region, requirements, and desired utilization rates with the many standard ‘in demand’ features and an ever-growing list of options.

With drill rig service shops in Pennsylvania, Florida, and Kansas, you’ll have industry-leading drill rig service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your drill rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new drill rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

Tier 4 Enhancements

Tier 4 engine enhancements provide additional horsepower and cost-savings hydraulic features

- POWER: Tier 4 engine provides more than 15% greater horsepower when compared to the previous version.

- AUTO THROTTLE: automatically senses the load and adjusts throttle accordingly, saving fuel.

- LOAD-SENSE HYDRAULICS: supplies the system pressure required to perform requested tasks, reducing heating of the hydraulic fluid — important when operating in elevated ambient temperatures and performing high-duty operations such as coring, augering, or tracking long distances.

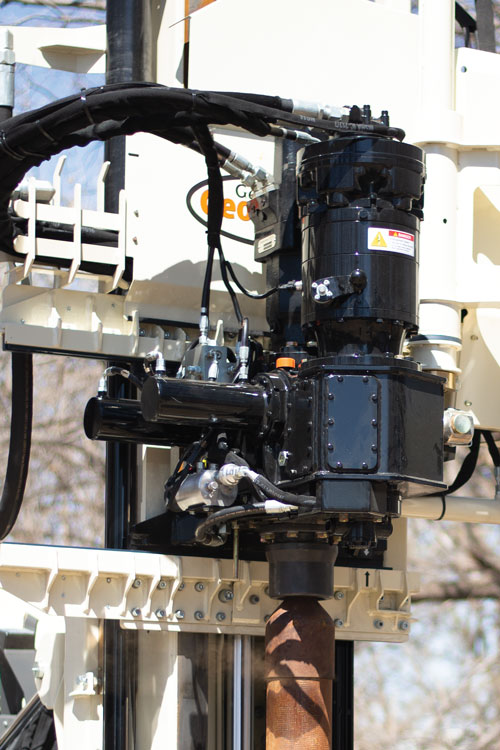

Patented CB Combo Head

CB Combo Head gives 3230DT drill rig rotary power and direct push precision

The patented CB Combo Head is the heart of the 3230DT and perfect for augering and high-speed rotary work. For projects that require direct push sampling or driving large casing, the integrated GH70 Hammer has become standard.

Completing the CB Combo Head is our built-in patented hydraulic head clamp, allowing users to safely and quickly hold or pull rods, casings, or augers while maintaining an open tool string. It easily manages the 80,000 lb. of pullback from the drill mast. Additionally, the combo head has functionality for direct push / percussion, mud rotary, air rotary, and rock coring.

Multi-function Drill Mast

Patented CB combo head allows for direct push with GH70 class hammer

Video: 3230DT Features - Telescoping Winch Mast

After running this rig for a short time, you’ll be impressed with how easy and conveniently the 3230DT transitions from driving casing via direct push to wet rotary drilling ... in less than five minutes. The patented CB Combo Head, designed and built exclusively by Geoprobe®, allows you to do direct push hammering for sampling and monitoring well installation.

The rotation function of the head allows for different drilling techniques, such as air rotary, wet rotary, overburden rotary systems, augering, and rock coring. The rotation function handles the full 80,000 lbf of pullback required for a machine of this magnitude. And with the integrated hydraulic head clamp, you can easily hold or pull rods, casings, or augers while maintaining an open top tool string.

Geotechnical Standard Penetration Testing (SPT) with the Automatic Drop Hammer provides for easy sampling through the inside diameter of both hollow stem augers or driven casing. Each function of the combo head opens up additional applications and services you can offer your customers. And you can do it all with ONE MACHINE!

Automatic Drop Hammer (Geotech)

Drop hammer for SPT work with the 3230DT drill rig

Video: 3230DT Geotechnical Features

The DH105 Automatic Drop Hammer is equipped for Standard Penetration Testing (SPT) work. The easy-to-use drop hammer hydraulically swings out over the borehole after the combo head is sideshifted away from the tool string. The DH105 comes standard with a 140 lb. slug or can be equipped with slugs ranging from 100 to 340 lb., depending upon your needs.

FEATURES

- Easy on / Easy off design

- Conforms to ASTM Standards D1586

- Consistent results

- No cables or ropes needed for operation

- Hammer swings over hole without repositioning the whole machine

- Throw height can be adjusted within seconds

- Use your Geoprobe® rig for both environmental & geotechnical projects

- SPT blow count results are used for obtaining strength & density properties of soil, designing foundations, & defining earthquake sensitive soils

Movable, Adjustable Control Panel

Swing arm control panel eliminates "driller's neck" for easier operation on 3230DT

Video: 3230DT Adjustable Control Panel

The adjustable swing-arm control panel with intuitive layout allows the operator to perform multiple tasks effortlessly. Speeds, feeds, and pumps can be precisely dialed in with the electronic controls. The control panel’s ability to swing freely from the rig lets the operator be in the position needed to help align a rod or to be at a comfortable distance away from a spinning drill string. Even controls to side-shift the Combo Head and reposition the Automatic Drop Hammer are at the operator’s fingertips.

FEATURES

- Swing Arm for multi-positioning options

- Integrated Electronic Diagnostic System: An integrated Systems Display on the control panel provides real-time systems analysis and a suite of built-in diagnostic tools. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised. It’s all there to assist the rig operator.

- Easy-to-Use, Organized Layout

- Digital Display Screen with Multi-function Output

- Integrated Head Feed Pressure Controls (optional): Adding the head feed pressure control option for rotary drilling takes the strain off the operator by eliminating the need to manually adjust head feed rate. Head feed pressure control provides consistent bit weight control for better penetration rates and longer bit life. It also permits effective hands-free operation with the addition of an interlocked rotation guard.

- Operator Presence Bar locks out controls when not engaged by operator

- Single Toggle Switch to go from Hammer to Rotation

- Variable Speed Control for Hammer and Rotation

- Variable Flow Control of Auxiliary Hydraulics

- Electric-Over-Hydraulic System for

- Head Functions

- Manual Valves for Machine Positioning

- Emergency Stop

- Lockable Control Panel Cover for transport and storage

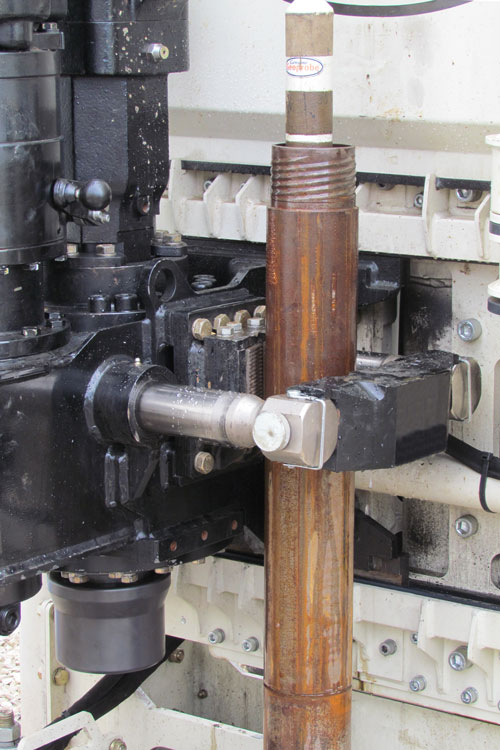

80K Pullback/50K Downforce with Patented Hydraulic Head Clamp

Patented hydraulic head clamp handles the 80,000 lb of drill rig pullback

The 3230DT drill mast may be one of the more unique aspects of this new offering. With a retraction force of 80,000 lbf at the cylinder and 84 inches of travel, the 3230DT has the pullback needed for direct push work.

If you’re using the Direct Push Hammer, you need to be able to pull casing back out of the ground. For that reason, engineers incorporated our patented hydraulic head clamp within the combo head to safely and quickly pull rods ranging from 1.25 to 6.0 in. OD while maintaining an open ID to speed up well installation. The built-in Head Clamp can handle the 80,000 lb. of the rig’s pullback.

Head Centerline Side Shift

Side shift positions the head over the hole or out of the way for the automatic drop hammer

Video: 3230DT Features - Head Centerline Side Shift

All of the machine’s functions are at your fingertips on the control panel, including the hydraulic controls for positioning the side-shift function of the CB Combo Head. The combo head travels up to 24 inches to the left and 2 inches to the right from center so you can work the inside diameter of the rod without moving the drill mast. When using the drop hammer, it hydraulically swings into place for operation over the hole.

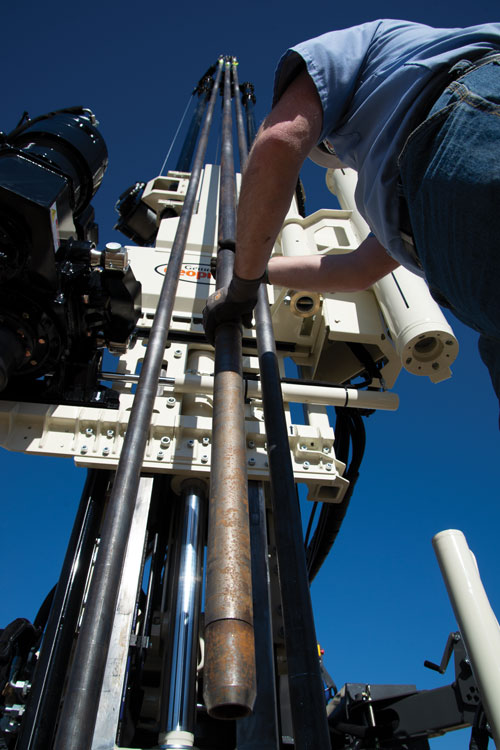

Triple Winch with Telescoping Mast

Triple winch on telescoping winch mast allows using 20-foot sections of tooling with the 3230DT drill rig

Video: 3230DT: Triple Winch Options

The variable height telescoping winch mast, with a maximum height of 24 feet, allows your field team to trip 20-foot sections of tooling. The 3230DT can also be operated with the winch mast lowered to work under power lines, inside buildings, or when canopies or structures require a lower clearance. The telescoping mast can be outfitted with one, two, or three winches depending on user preference.

Features

- Line pulls up to 8,500 lbf and line speeds up to 191 fpm

- Telescoping winch mast hydraulically raises and lowers, variable operating heights

- Trip 20-foot. sections of tooling

- Maximum height of 24 feet

Drill Mast Outriggers

Optional outriggers for additional stability

Optional front outriggers help keep the drill mast steady while drilling. With a 26-inch stroke, the drill mast can be left up while lowering the outriggers to have room for a mud pan, for using a breakout above the casing, or just to have extra room while augering.

Wireless and Tethered Remote Drive

Wireless remote allows for operation from a safe distance

Video: 3230DT Features - Remotes

The 3230DT comes with a wireless remote and a tethered remote. Features of the wireless remote include:

- Throttle Up / Throttle Down

- Raise and Lower the Blade

- Adjust Speeds (3)

- Paddles to Drive Tracks Independently

- E-Stop Switch

- Remote Uses Standard AA Batteries

Safety Features

Optional rotation guard for added safety

Safety was a top consideration in the design and engineering of the 3230DT. Safety features include:

- Emergency stop on the control panel, wireless remote, tethered remote, and back of the machine instantly stop the rig

- Operator Presence Bar on the control panel locks out controls when not engaged by the operator

- Optional Rotation Guard

- Fire Extinguisher on the machine

Breakout Kits

9-inch double clamp pullback breakout kit

Video: 3230DT Features - 7 in Breakout Kit

With an adjustable clamp force of up to 17,500 lbf, the 3230DT breakout has an opening of 7 inches with hardened jaw pads to firmly grip casing. The breakout has a side pivot allowing it to swing over and away from the hole when not in use. An optional Coring Upgrade Kit (217024) is also available to firmly grip thin-walled 2.75-inch OD casing without damage to the casing. The kit includes formed jaw pads and a circle wrench with carbide inserts.

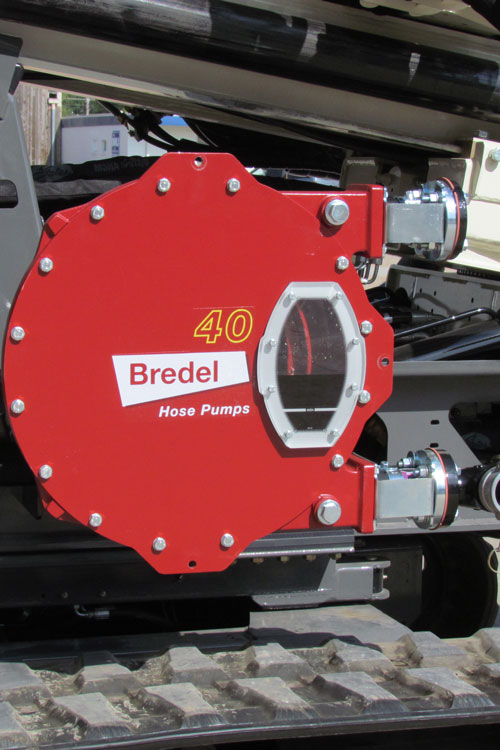

Water/Mud Pumps

3230DT drill rig offers a variety of pump options

Separate mud pump circuit eliminates the battle between drilling functions and fluid circulation for hydraulic flow and pressure, creating stable mud flow.

A number of pumps are available for the 3230DT. These include:

- Progressive Cavity Pumps

- Hose Pumps

- Triplex Pump Kit

Pumps are typically used for mud rotary and rock coring applications.

Features & Options

Video: Geoprobe® 3230DT Overview

Owners praise their Geoprobe® 3230DT drill rig for their ability to compete for geotechnical projects while expanding their environmental work. With numerous features and configurations for success, crews rely on the 3230DT combination drill rig for its power and precision.

- TASKS: possess power for hollow stem augers along with finesse for high-speed wireline tools with the torque and rotary range of the patented CB combo head. Experience versatility with ease by adding a powerful GH70 hammer, switching between tasks quickly. Need to auger to bedrock and then do a confirmation core? You’re ready with ONE MACHINE.

- TRANSITIONS: work the inside diameter of the rod without moving the drill mast thanks to head travel along center. Conveniently transition from driving casing via direct push to wet rotary drilling ... in less than five minutes. Hold or pull rods, casings, or augers while maintaining an open tool string using the patented hydraulic head clamp, which easily manages the 80,000 lb. of pullback.

- TAILORED: customize site setup by positioning the telescoping winch mast as well as the height and angle of the adjustable swing-arm control panel, steering clear of spinning tool strings or positioning comfortably close to align rods. Precisely dial in speeds, feeds, and pumps with the intuitive electronic controls. Equip the rig for your region, requirements, and desired utilization rates with the many standard ‘in demand’ features and an ever-growing list of options.

With drill rig service shops in Pennsylvania, Florida, and Kansas, you’ll have industry-leading drill rig service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your drill rig is constructed consistently and tested thoroughly to ensure easier service support.

Don't see a feature you're looking for on your new drill rig? Give us a call.

Our team of engineers thrives on collaborating with drillers while they continually innovate new designs.

- POWER: Tier 4 engine provides more than 15% greater horsepower when compared to the previous version.

- AUTO THROTTLE: automatically senses the load and adjusts throttle accordingly, saving fuel.

- LOAD-SENSE HYDRAULICS: supplies the system pressure required to perform requested tasks, reducing heating of the hydraulic fluid — important when operating in elevated ambient temperatures and performing high-duty operations such as coring, augering, or tracking long distances.

The patented CB Combo Head is the heart of the 3230DT and perfect for augering and high-speed rotary work. For projects that require direct push sampling or driving large casing, the integrated GH70 Hammer has become standard.

Completing the CB Combo Head is our built-in patented hydraulic head clamp, allowing users to safely and quickly hold or pull rods, casings, or augers while maintaining an open tool string. It easily manages the 80,000 lb. of pullback from the drill mast. Additionally, the combo head has functionality for direct push / percussion, mud rotary, air rotary, and rock coring.

After running this rig for a short time, you’ll be impressed with how easy and conveniently the 3230DT transitions from driving casing via direct push to wet rotary drilling ... in less than five minutes. The patented CB Combo Head, designed and built exclusively by Geoprobe®, allows you to do direct push hammering for sampling and monitoring well installation.

The rotation function of the head allows for different drilling techniques, such as air rotary, wet rotary, overburden rotary systems, augering, and rock coring. The rotation function handles the full 80,000 lbf of pullback required for a machine of this magnitude. And with the integrated hydraulic head clamp, you can easily hold or pull rods, casings, or augers while maintaining an open top tool string.

Geotechnical Standard Penetration Testing (SPT) with the Automatic Drop Hammer provides for easy sampling through the inside diameter of both hollow stem augers or driven casing. Each function of the combo head opens up additional applications and services you can offer your customers. And you can do it all with ONE MACHINE!

Video: 3230DT Features - Telescoping Winch Mast

The DH105 Automatic Drop Hammer is equipped for Standard Penetration Testing (SPT) work. The easy-to-use drop hammer hydraulically swings out over the borehole after the combo head is sideshifted away from the tool string. The DH105 comes standard with a 140 lb. slug or can be equipped with slugs ranging from 100 to 340 lb., depending upon your needs.

FEATURES

- Easy on / Easy off design

- Conforms to ASTM Standards D1586

- Consistent results

- No cables or ropes needed for operation

- Hammer swings over hole without repositioning the whole machine

- Throw height can be adjusted within seconds

- Use your Geoprobe® rig for both environmental & geotechnical projects

- SPT blow count results are used for obtaining strength & density properties of soil, designing foundations, & defining earthquake sensitive soils

Video: 3230DT Geotechnical Features

The adjustable swing-arm control panel with intuitive layout allows the operator to perform multiple tasks effortlessly. Speeds, feeds, and pumps can be precisely dialed in with the electronic controls. The control panel’s ability to swing freely from the rig lets the operator be in the position needed to help align a rod or to be at a comfortable distance away from a spinning drill string. Even controls to side-shift the Combo Head and reposition the Automatic Drop Hammer are at the operator’s fingertips.

FEATURES

- Swing Arm for multi-positioning options

- Integrated Electronic Diagnostic System: An integrated Systems Display on the control panel provides real-time systems analysis and a suite of built-in diagnostic tools. Also included are system safeguards that protect the main engine and hydraulic components when important operational parameters are compromised. It’s all there to assist the rig operator.

- Easy-to-Use, Organized Layout

- Digital Display Screen with Multi-function Output

- Integrated Head Feed Pressure Controls (optional): Adding the head feed pressure control option for rotary drilling takes the strain off the operator by eliminating the need to manually adjust head feed rate. Head feed pressure control provides consistent bit weight control for better penetration rates and longer bit life. It also permits effective hands-free operation with the addition of an interlocked rotation guard.

- Operator Presence Bar locks out controls when not engaged by operator

- Single Toggle Switch to go from Hammer to Rotation

- Variable Speed Control for Hammer and Rotation

- Variable Flow Control of Auxiliary Hydraulics

- Electric-Over-Hydraulic System for

- Head Functions

- Manual Valves for Machine Positioning

- Emergency Stop

- Lockable Control Panel Cover for transport and storage

Video: 3230DT Adjustable Control Panel

The 3230DT drill mast may be one of the more unique aspects of this new offering. With a retraction force of 80,000 lbf at the cylinder and 84 inches of travel, the 3230DT has the pullback needed for direct push work.

If you’re using the Direct Push Hammer, you need to be able to pull casing back out of the ground. For that reason, engineers incorporated our patented hydraulic head clamp within the combo head to safely and quickly pull rods ranging from 1.25 to 6.0 in. OD while maintaining an open ID to speed up well installation. The built-in Head Clamp can handle the 80,000 lb. of the rig’s pullback.

All of the machine’s functions are at your fingertips on the control panel, including the hydraulic controls for positioning the side-shift function of the CB Combo Head. The combo head travels up to 24 inches to the left and 2 inches to the right from center so you can work the inside diameter of the rod without moving the drill mast. When using the drop hammer, it hydraulically swings into place for operation over the hole.

Video: 3230DT Features - Head Centerline Side Shift

The variable height telescoping winch mast, with a maximum height of 24 feet, allows your field team to trip 20-foot sections of tooling. The 3230DT can also be operated with the winch mast lowered to work under power lines, inside buildings, or when canopies or structures require a lower clearance. The telescoping mast can be outfitted with one, two, or three winches depending on user preference.

Features

- Line pulls up to 8,500 lbf and line speeds up to 191 fpm

- Telescoping winch mast hydraulically raises and lowers, variable operating heights

- Trip 20-foot. sections of tooling

- Maximum height of 24 feet

Video: 3230DT: Triple Winch Options

Optional front outriggers help keep the drill mast steady while drilling. With a 26-inch stroke, the drill mast can be left up while lowering the outriggers to have room for a mud pan, for using a breakout above the casing, or just to have extra room while augering.

The 3230DT comes with a wireless remote and a tethered remote. Features of the wireless remote include:

- Throttle Up / Throttle Down

- Raise and Lower the Blade

- Adjust Speeds (3)

- Paddles to Drive Tracks Independently

- E-Stop Switch

- Remote Uses Standard AA Batteries

Video: 3230DT Features - Remotes

Safety was a top consideration in the design and engineering of the 3230DT. Safety features include:

- Emergency stop on the control panel, wireless remote, tethered remote, and back of the machine instantly stop the rig

- Operator Presence Bar on the control panel locks out controls when not engaged by the operator

- Optional Rotation Guard

- Fire Extinguisher on the machine

With an adjustable clamp force of up to 17,500 lbf, the 3230DT breakout has an opening of 7 inches with hardened jaw pads to firmly grip casing. The breakout has a side pivot allowing it to swing over and away from the hole when not in use. An optional Coring Upgrade Kit (217024) is also available to firmly grip thin-walled 2.75-inch OD casing without damage to the casing. The kit includes formed jaw pads and a circle wrench with carbide inserts.

Video: 3230DT Features - 7 in Breakout Kit

Separate mud pump circuit eliminates the battle between drilling functions and fluid circulation for hydraulic flow and pressure, creating stable mud flow.

A number of pumps are available for the 3230DT. These include:

- Progressive Cavity Pumps

- Hose Pumps

- Triplex Pump Kit

Pumps are typically used for mud rotary and rock coring applications.

“To me paying for an auger drilling rig or rotary drilling rig limited unit is a lot to pay versus the additional for a multi-application capable 3230DT based on the return. With the larger head and additional weight of the 3230DT we can now run 6 and 8-inch DTH hammers with larger API rods very efficiently.”

- Cory Walker, Owner, Hawkston LLC, Tennessee

Tooling & Accessories

Video: Geoprobe® 3230DT - Driving 3.75 in. Tooling to 30 Feet

The DT37 Soil Sampling System, designed for use with 3.75-inch probe rods, uses a unique combination of the cutting shoe, sheath, and liner retainer to allow efficient recovery of samples in formations ranging from plastic clays to saturated sands. The DT37 system is designed to quickly recover samples well below the water table. Problems with liner failure or having the liner lodge in sample sheath are virtually eliminated with this system.

The DT45 Sampling System is specifically designed for use with the Geoprobe® 3230DT. This sampler provides a cased hole while providing a 3-inch diameter core sample. The durable DT45 Sampling System uses the Geoprobe® 4.5-inch probe rods as the outer casing along with the option of using standard 1.25-inch or 2.25-inch probe rods as inner casing to pull core samples.

Video: DT60 Soil Sampling System Overview

The DT60 sampling system is the largest dual tube system from Geoprobe®. It utilizes 6-inch OD percussion driven casing and collects a 4-inch diameter soil sample. Unlike most other sampling systems, the DT60 uses a patented split sheath which gives the user the option of not using a liner.In addition to its soil sampling capacity, the DT60 system can also be used to install 2-inch monitoring wells without driving a second tool string. That means you can collect continuous soil cores and install a 2-inch prepack or conventional well within a 6-inch borehole with no expendable points or cutting shoes – all in one shot!

Video: Interlocking Split Spoon Overview

Engineered to be stronger, last longer, and save money and time, the patented interlocking split spoon meets ASTM Standard D1586.The finger-like design self aligns, creating a perfect fit and quicker assembly. With the threads aligned, the cutting shoe and drive head can be threaded to the split spoon. Multi-lead threads require fewer turns during assembly and disassembly over conventional split spoons, speeding up each test interval.In additional to time savings, enhanced material properties and manufacturing result in greater longevity. Each interlocking point keeps the two tube halves engaged throughout the sampling process. The strength of these connections prevents the sampler from bulging in dense materials. It also keeps the tube halves tightly engaged even when over-filling of the sampler occurs.

Video: SP22-ISP Groundwater Sampler

The Screen Point 22 (SP22) Groundwater Sampler from Geoprobe Systems® was designed to keep the screen away from all percussive energy while the sampler is lowered downhole, thus extending the life of the screen.The SP22 can be used alone as a groundwater grab sampler or groundwater profiling tool, or with the DT22 Soil Sampling System. The screens can be deployed using either 1.25-inch Lightweight Center Rods or PVC riser.Designed for tough probing conditions, the screen head on the fully retrievable sampler adapts to either a stainless steel or PVC screen.

Video: Geoprobe® Hydraulic Liner Extruder

This tool sure makes life easier in the field. In the middle of a busy day, you don’t need the hassles associated with a stubborn, stuck liner. The Geoprobe® Hydraulic Liner Extruder is simple to use and can be adapted to most Geoprobe® machines with auxiliary hydraulics. A two-piece adapter converts the extruder assembly to accommodate larger diameter DT325 sample tubes. Using the Hydraulic Liner Extruder is simple. A Macro-Core®, DT22, DT325, or DT45 Sample Tube with the sluggish liner is threaded on to the front end of the extruder. As the hydraulic "push" is applied to the opposite end of the extruder, the liner is slowly pushed from inside the Sample Tube and out the end of the extruder. Macro-Core® is a registered trademark of Kejr, Inc., Salina, KS.

Video: Geoprobe® Spring Assisted Swivel Lift Cap

The Spring Assisted Swivel Lift Cap is designed to reduce operator fatigue when adding or removing sections of rods to the inner tool string. The internal springs of the pull cap bear the weight of the rod string. With minimal effort, the operator can adjust the rod string up or down when threading or unthreading the rods. The natural self-alignment of the rod string prevents tipping off center and binding of the threads.

Applications

Videos

3230DT Walkaround - Control Panel

ID: 13627

Geoprobe® MD4 Display Overview

ID: 13461

ID: 216

ID: 221

ID: 224

ID: 1906

ID: 1955

ID: 220

ID: 261

ID: 222

Testimonial - 3230DT Rock Coring

ID: 1966

ID: 1967

Specs

Specifications are subject to change without notice.

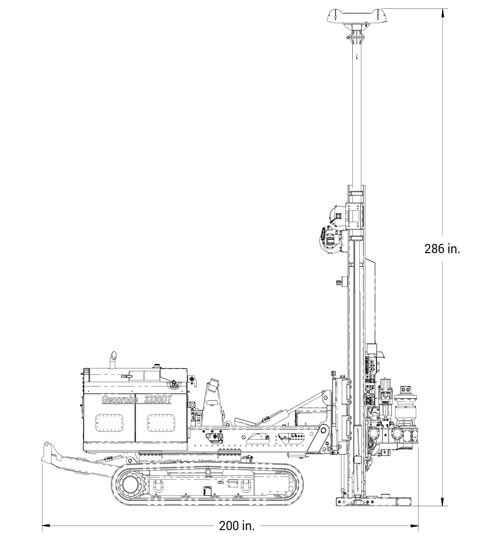

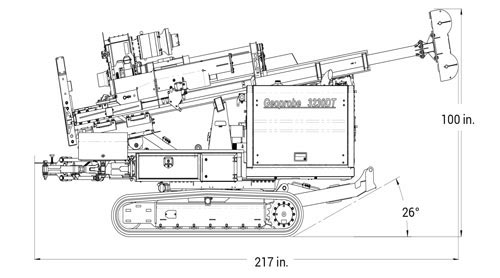

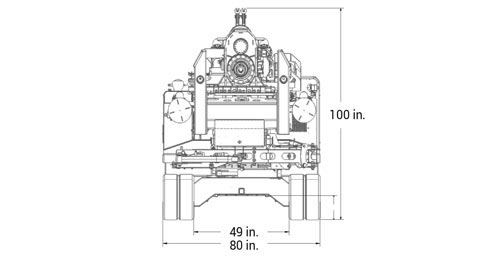

| 3230DT T4 | 3230DT T4 | ||

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 83 | Width (mm) | 2108 |

| Length (transport) (in) | 217 | Length (transport) (mm) | 5512 |

| Length (deployed, lateral fully extended) (in) | 200 | Length (deployed, lateral fully retracted) (mm) | 5080 |

| Height (normal transport) (in) | 100 | Height (normal transport) (mm) | 2540 |

| Height (deployed; winch mast up) (in) | 286 | Height (deployed; winch mast up) (mm) | 7264 |

| Height (deployed; winch mast up) (ft) | 23.8 | Height (deployed; winch mast up) (m) | 7.26 |

| Approach/departure angle in transport (degrees) | 24 | Approach/departure angle in transport (degrees) | 24 |

| Base Unit Weight (lbs) | 17,500 | Base Unit Weight (kg) | 7,938 |

| Unit Weight (w/ typical options) lbs | 20,500 | Unit Weight (w/ typical options) kg | 9,299 |

| Ground Speed (mph) | 2.7 | Ground Speed (kph) | 4.3 |

| Estimated Track Surface Area (in2) | 1958 | Estimated Track Surface Area (cm2) | 12629 |

| Estimated Track Surface Area -- 6" penetration (in2) | 3056 | Estimated Track Surface Area -- 15 cm penetration (cm2) | 19708 |

| Estimated Ground Pressure (psi) (0" penetration) | 8.9 | Estimated Ground Pressure (bar) (0 cm penetration) | 0.6 |

| Estimated Ground Pressure (psi) (6" penetration) | 5.7 | Estimated Ground Pressure (bar) (15 cm penetration) | 0.4 |

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 11 | Extension (fore and aft) (mm) | 279 |

| Lateral (side to side) (± degrees) | 8 | Lateral (side to side) (± degrees) | 8 |

| Oscillation (degrees from vertical) | 11 | Oscillation (degrees from vertical) | 11 |

| Drill Mast Dump (in) | 25 | Drill Mast Dump (mm) | 635 |

| Front outrigger travel (in) | NA | Front outrigger travel (mm) | NA |

| Rear stabilizer travel (in) | 26 | Rear outrigger travel (mm) | 660 |

| Rear stabilizer width (in) | 78 | Rear stabilizer width (mm) | 1981 |

| Rear stabilizer lift (lbs) | 3000 | Rear stabilizer lift (kg) | 1361 |

| Max angle drilling ability off vertical (degrees) | 45 | Max angle drilling ability off vertical (degrees) | 45 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 84 | Head Travel (mm) | 2134 |

| Head Travel (ft) | 7.0 | Head Travel (m) | 2.13 |

| Head Crowd Force (lbs) | 50,000 | Head Crowd Force (kN) | 222 |

| Head Pull Force (lbs) | 80,000 | Head Pull Force (kN) | 356 |

| Head Feed Rate Down (fpm) | 60 | Head Feed Rate Down (m/min) | 18 |

| Head Feed Rate Up (regen) (fpm) | 93 | Head Feed Rate Up (regen) (m/min) | 28 |

| Head Feed Rate Up (non-regen) (fpm) | 46 | Head Feed Rate Up (non-regen) (m/min) | 14 |

| Head Feed Carriage | Comp. slides | Head Feed Carriage | Comp. slides |

| Head Feed Pressure Control (w.o.b) | Optional | Head Feed Pressure Control (w.o.b) | Optional |

| Head Sideshift (in) | 26 | Head Sideshift (mm) | 660 |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | Kubota V3800 Tier 4 | Engine | Kubota V3800 Tier 4 |

| Engine Rated Power (hp) | 114 | Engine Rated Power (kW) | 85 |

| Fuel Capacity (gal) | 40 | Fuel Capacity (L) | 151 |

| Pump type | Axial Piston - HP limited -- LS | Pump type | Axial Piston - HP limited -- LS |

| Max pressure (psi) | 4,000 | Max pressure (bar) | 276 |

| Max flow (gpm) | 72 | Max flow (L/min) | 273 |

| Additional Pump | Variable Speed Fan Pump | Additional Pump | Variable Speed Fan Pump |

| Direct Push Hammer Options | Direct Push Hammer Options | ||

| GH70 | GH70 | ||

| Rotary Drive Options | Rotary Drive Options | ||

| 4-speed | 4-speed | ||

| Rotation Torque (Range 1) (ft-lb) | 6000 | Rotation Torque (Range 1) (N-m) | 8135 |

| Rotation Speed (Range 1) (rpm) | 75 | Rotation Speed (Range 1) (rpm) | 75 |

| Rotation Torque (Range 4) (ft-lb) | 600 | Rotation Torque (Range 4) (N-m) | 813 |

| Rotation Speed (Range 4) (rpm) | 800 | Rotation Speed (Range 4) (rpm) | 800 |

| Standard Winch (Position 1) | Standard Winch (Position 1) | ||

| line pull (lbf) | 8500 | line pull (kN) | 37.81 |

| line speed (fpm) | 115 | line speed (m/min) | 35 |

| cable length (ft) | 150 | cable length (m) | 46 |

| cable diameter (in) | 0.5 | cable diameter (mm) | 13 |

| line pull (lbf) | 5000 | line pull (kN) | 22.24 |

| line speed (fpm) | 130 | line speed (m/min) | 40 |

| cable length (ft) | 125 | cable length (m) | 38 |

| cable diameter (in) | 0.375 | cable diameter (mm) | 10 |

| Second Winch (Position 2) | Second Winch (Position 2) | ||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 |

| line speed (fpm) | 110 | line speed (m/min) | 34 |

| cable length (ft) | 175 | cable length (m) | 53 |

| cable diameter (in) | 0.25 | cable diameter (mm) | 6 |

| line pull (lbf) | 1100 | line pull (kN) | 4.89 |

| line speed (fpm) | 230 | line speed (m/min) | 70 |

| cable length (ft) | 250 | cable length (m) | 76 |

| cable diameter (in) | 0.188 | cable diameter (mm) | 5 |

| Third Winch (Position 3) | Third Winch (Position 3) | ||

| line pull (lbf) | 1100 | line pull (kN) | 4.89 |

| line speed (fpm) | 191 | line speed (m/min) | 58 |

| cable length (ft) | 750 | cable length (m) | 229 |

| cable diameter (in) | 0.188 | cable diameter (mm) | 5 |

| line pull (lbf) | 1800 | line pull (kN) | 8.01 |

| line speed (fpm) | 190 | line speed (m/min) | 58 |

| cable length (ft) | 175 | cable length (m) | 53 |

| cable diameter (in) | 0.25 | cable diameter (mm) | 6 |

| Triplex Water Pump | Triplex Water Pump | ||

| Max pressure (psi) | 750 | Max pressure (bar) | 52 |

| Max flow (gpm) | 25 | Max flow (L/min) | 95 |

| Auto Drop Hammer | Auto Drop Hammer | ||

| Drop height (in) | 30 | Drop height (mm) | 762 |

| Float (in) | 31 | Float (mm) | 787 |

| Breakout | Breakout | ||

| Pullback (Double) | Pullback (Double) | ||

| Max Clamp force (lbf) | 21,000 | Clamp force (kN) | 93.41 |

| Breakout torque (ft-lb) | 13,900 | Breakout torque (N-m) | 18846 |

| Min Casing size compatible (in) | 2.25 | Min Casing size compatible (mm) | 57 |

| Max Casing size compatible (in) | 8.63 | Max Casing size compatible (mm) | 219 |

| Vertical travel (in) | 12 | Vertical travel (mm) | 305 |

| Single Clamp | Single Clamp | ||

| Max Clamp force (lbf) | 17,500 | Clamp force (kN) | 77.84 |

| Breakout torque (ft-lb) | 6,000 | Breakout torque (N-m) | 8135 |

| Min Casing size compatible (in) | 1.25 | Min Casing size compatible (mm) | 32 |

| Max Casing size compatible (in) | 6 | Max Casing size compatible (mm) | 152 |

| Vertical travel (in) | NA | Vertical travel (mm) | NA |

Specs

Click below to view standard specifications. Specifications are subject to change without notice.

| 3230DT T4 | 3230DT T4 | ||

| Overall Dimensions | Overall Dimensions | ||

| Width (in) | 83 | Width (mm) | 2108 |

| Length (transport) (in) | 217 | Length (transport) (mm) | 5512 |

| Length (deployed, lateral fully extended) (in) | 200 | Length (deployed, lateral fully retracted) (mm) | 5080 |

| Height (normal transport) (in) | 100 | Height (normal transport) (mm) | 2540 |

| Height (deployed; winch mast up) (in) | 286 | Height (deployed; winch mast up) (mm) | 7264 |

| Height (deployed; winch mast up) (ft) | 23.8 | Height (deployed; winch mast up) (m) | 7.26 |

| Approach/departure angle in transport (degrees) | 24 | Approach/departure angle in transport (degrees) | 24 |

| Base Unit Weight (lbs) | 17,500 | Base Unit Weight (kg) | 7,938 |

| Unit Weight (w/ typical options) lbs | 20,500 | Unit Weight (w/ typical options) kg | 9,299 |

| Ground Speed (mph) | 2.7 | Ground Speed (kph) | 4.3 |

| Estimated Track Surface Area (in2) | 1958 | Estimated Track Surface Area (cm2) | 12629 |

| Estimated Track Surface Area -- 6" penetration (in2) | 3056 | Estimated Track Surface Area -- 15 cm penetration (cm2) | 19708 |

| Estimated Ground Pressure (psi) (0" penetration) | 8.9 | Estimated Ground Pressure (bar) (0 cm penetration) | 0.6 |

| Estimated Ground Pressure (psi) (6" penetration) | 5.7 | Estimated Ground Pressure (bar) (15 cm penetration) | 0.4 |

| Drill Mast Positioning | Drill Mast Positioning | ||

| Extension (fore and aft) (in) | 11 | Extension (fore and aft) (mm) | 279 |

| Lateral (side to side) (± degrees) | 8 | Lateral (side to side) (± degrees) | 8 |

| Oscillation (degrees from vertical) | 11 | Oscillation (degrees from vertical) | 11 |

| Drill Mast Dump (in) | 25 | Drill Mast Dump (mm) | 635 |

| Front outrigger travel (in) | NA | Front outrigger travel (mm) | NA |

| Rear stabilizer travel (in) | 26 | Rear outrigger travel (mm) | 660 |

| Rear stabilizer width (in) | 78 | Rear stabilizer width (mm) | 1981 |

| Rear stabilizer lift (lbs) | 3000 | Rear stabilizer lift (kg) | 1361 |

| Max angle drilling ability off vertical (degrees) | 45 | Max angle drilling ability off vertical (degrees) | 45 |

| Drill Mast Specifications | Drill Mast Specifications | ||

| Head Travel (in) | 84 | Head Travel (mm) | 2134 |

| Head Travel (ft) | 7.0 | Head Travel (m) | 2.13 |

| Head Crowd Force (lbs) | 50,000 | Head Crowd Force (kN) | 222 |

| Head Pull Force (lbs) | 80,000 | Head Pull Force (kN) | 356 |

| Head Feed Rate Down (fpm) | 60 | Head Feed Rate Down (m/min) | 18 |

| Head Feed Rate Up (regen) (fpm) | 93 | Head Feed Rate Up (regen) (m/min) | 28 |

| Head Feed Rate Up (non-regen) (fpm) | 46 | Head Feed Rate Up (non-regen) (m/min) | 14 |

| Head Feed Carriage | Comp. slides | Head Feed Carriage | Comp. slides |

| Head Feed Pressure Control (w.o.b) | Optional | Head Feed Pressure Control (w.o.b) | Optional |

| Head Sideshift (in) | 26 | Head Sideshift (mm) | 660 |

| Prime Mover & Hydraulic Specs | Prime Mover & Hydraulic Specs | ||

| Engine | Kubota V3800 Tier 4 | Engine | Kubota V3800 Tier 4 |

| Engine Rated Power (hp) | 114 | Engine Rated Power (kW) | 85 |

| Fuel Capacity (gal) | 40 | Fuel Capacity (L) | 151 |

| Pump type | Axial Piston - HP limited -- LS | Pump type | Axial Piston - HP limited -- LS |

| Max pressure (psi) | 4,000 | Max pressure (bar) | 276 |

| Max flow (gpm) | 72 | Max flow (L/min) | 273 |

| Additional Pump | Variable Speed Fan Pump | Additional Pump | Variable Speed Fan Pump |

| Direct Push Hammer Options | Direct Push Hammer Options | ||

| GH70 | GH70 | ||

| Rotary Drive Options | Rotary Drive Options | ||

| 4-speed | 4-speed | ||

| Rotation Torque (Range 1) (ft-lb) | 6000 | Rotation Torque (Range 1) (N-m) | 8135 |

| Rotation Speed (Range 1) (rpm) | 75 | Rotation Speed (Range 1) (rpm) | 75 |

| Rotation Torque (Range 4) (ft-lb) | 600 | Rotation Torque (Range 4) (N-m) | 813 |

| Rotation Speed (Range 4) (rpm) | 800 | Rotation Speed (Range 4) (rpm) | 800 |

| Standard Winch (Position 1) | Standard Winch (Position 1) | ||

| line pull (lbf) | 8500 | line pull (kN) | 37.81 |

| line speed (fpm) | 115 | line speed (m/min) | 35 |

| cable length (ft) | 150 | cable length (m) | 46 |

| cable diameter (in) | 0.5 | cable diameter (mm) | 13 |

| line pull (lbf) | 5000 | line pull (kN) | 22.24 |

| line speed (fpm) | 130 | line speed (m/min) | 40 |

| cable length (ft) | 125 | cable length (m) | 38 |

| cable diameter (in) | 0.375 | cable diameter (mm) | 10 |

| Second Winch (Position 2) | Second Winch (Position 2) | ||

| line pull (lbf) | 1800 | line pull (kN) | 8.01 |

| line speed (fpm) | 110 | line speed (m/min) | 34 |

| cable length (ft) | 175 | cable length (m) | 53 |

| cable diameter (in) | 0.25 | cable diameter (mm) | 6 |

| line pull (lbf) | 1100 | line pull (kN) | 4.89 |

| line speed (fpm) | 230 | line speed (m/min) | 70 |

| cable length (ft) | 250 | cable length (m) | 76 |

| cable diameter (in) | 0.188 | cable diameter (mm) | 5 |

| Third Winch (Position 3) | Third Winch (Position 3) | ||

| line pull (lbf) | 1100 | line pull (kN) | 4.89 |

| line speed (fpm) | 191 | line speed (m/min) | 58 |

| cable length (ft) | 750 | cable length (m) | 229 |

| cable diameter (in) | 0.188 | cable diameter (mm) | 5 |

| line pull (lbf) | 1800 | line pull (kN) | 8.01 |

| line speed (fpm) | 190 | line speed (m/min) | 58 |

| cable length (ft) | 175 | cable length (m) | 53 |

| cable diameter (in) | 0.25 | cable diameter (mm) | 6 |

| Triplex Water Pump | Triplex Water Pump | ||

| Max pressure (psi) | 750 | Max pressure (bar) | 52 |

| Max flow (gpm) | 25 | Max flow (L/min) | 95 |

| Auto Drop Hammer | Auto Drop Hammer | ||

| Drop height (in) | 30 | Drop height (mm) | 762 |

| Float (in) | 31 | Float (mm) | 787 |

| Breakout | Breakout | ||

| Pullback (Double) | Pullback (Double) | ||

| Max Clamp force (lbf) | 21,000 | Clamp force (kN) | 93.41 |

| Breakout torque (ft-lb) | 13,900 | Breakout torque (N-m) | 18846 |

| Min Casing size compatible (in) | 2.25 | Min Casing size compatible (mm) | 57 |

| Max Casing size compatible (in) | 8.63 | Max Casing size compatible (mm) | 219 |

| Vertical travel (in) | 12 | Vertical travel (mm) | 305 |

| Single Clamp | Single Clamp | ||

| Max Clamp force (lbf) | 17,500 | Clamp force (kN) | 77.84 |

| Breakout torque (ft-lb) | 6,000 | Breakout torque (N-m) | 8135 |

| Min Casing size compatible (in) | 1.25 | Min Casing size compatible (mm) | 32 |

| Max Casing size compatible (in) | 6 | Max Casing size compatible (mm) | 152 |

| Vertical travel (in) | NA | Vertical travel (mm) | NA |

Helper Side - Unfolded

Operator Side - Folded

Front - Folded

Resources

Click on a section below to view information.

Initially seeing drilling as a route toward a career in consulting, Kyle Brown discovered he liked drilling more than engineering. So, when the industry in Alberta, Canada, slowed down during 2015 he saw it as the perfect opportunity to launch his own bus

ID: 13406 | Date:

Landing a barge project, ODYSSEY ENVIRONMENTAL SERVICES Owner and Project Manager Jason Miller knew he needed to run tooling beyond the capabilities of his fleet of three 7822DTs. The predominantly environmental and geotechnical drilling company in Pennsy

ID: 13405 | Date:

3230DT versatility as all engineering-type rig - environmental, geotechnical, and CPT - in a single, relatively compact package has advantage of a second hydraulic circuit for mud pump to serve as efficient mud rotary drill.

ID: 12389 | Date:

Changes to 3.75 tooling improves fit with standard NWL coring bits.

ID: 5760 | Date:

Depend on Team Geoprobe®

Since 1987, Geoprobe® has manufactured innovative drilling rigs and tooling - engineered for efficiency and safety - simplifying drillers’ jobs and empowering their companies to succeed as productive and profitable leaders in the industry. When you partner with Geoprobe® you receive:

Customer-inspired Innovation

Engineering and building industry-leading drilling rigs, tooling, and techniques for the technical driller based on your needs to work safer and more efficiently.

Exceptional Value

Ensuring drilling rigs and tooling are created in conjunction – with consistent quality – to collect the highest-quality information with the most accurate result to get you to, into, and through the job efficiently.

Superior Service

Equipping you to do your best job and keeping you in the field via one-on-one expert sales and service technicians manning live support phone lines, shipping necessary parts same-day.